Squeeze Film Dampers:

Effect of Central Groove on identified force coefficients

MAJOR APPLICATION: Attenuate vibrations and isolate the rotating components from

the engine structure

Sponsors: Pratt & Whitney Engines,

Objective: To assess the forced dynamic performance

of two parallel SFDs for various geometries and end conditions, and to develop

a SFD predictive code benchmarked against test data

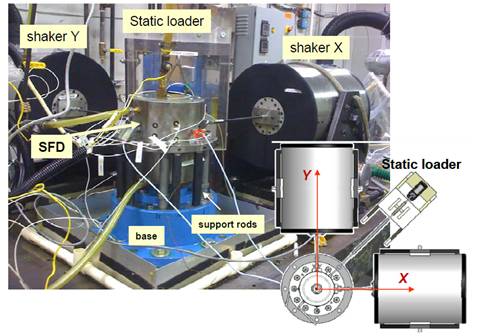

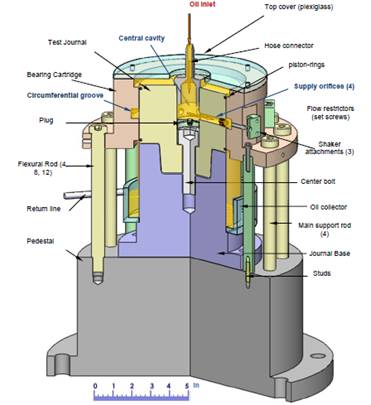

Status: A SFD test rig is designed to sponsor

specifications, manufactured and assembled in the laboratory. The test rig is highly modular in

construction – the geometry, squirrel cage support stiffness, lubricant supply

arrangement and end conditions can be quickly reconfigured. A static loader enables

SFD operation on static off-centered positions. Electromagnetic shakers (500 lbf)

deliver dynamic excitations to the test structure along two orthogonal

directions. A data acquisition and control code controls the shakers and

acquires data from a multiple sensors.

Current Work

Test rig is assembled

and fully operational. Frequency domain parameter identification procedures are

developed. SFD added mass (inertia) and damping coefficients are identified for

two SFD land lengths, multiple support stiffnesses and active lubricant feeding

holes, lubricant flow rates and groove pressures, and open and sealed end

conditions. A computational FORTRAN® code using a finite element

formulation of the Reynolds equation is developed. The predictions of SFD added

mass and damping coefficients are benchmarked against experimental coefficients

TEST FACILITY

TEST RIG STRUCTURE

Updated Jan 21, 2011