Gas Bearings for

Oil-Free Turbomachinery

MAJOR APPLICATION: Oil-Free Turbomachinery, Micro-Turbines,

etc

Sponsors:

Turbomachinery Research

Consortium (00-08), State of

Objective: To advance the technology of inexpensive gas bearings for

micro gas turbines and micro power systems

Status: Hybrid flexure

pivot tilting-pad gas bearings (FPTPB) can afford much higher operating speed

than conventional gas bearings, i.e. as high as 100 krpm, which is the maximum

speed the motor can provide. Moreover, computational model are available to predict

gas bearing damping and stiffness coefficients. Measurements in progress to

identify the test bearings’ dynamic force coefficients.

è To learn more,

order/read our PUBLICATIONS

2007-08

Work

FPTPBs can

operate at very high speeds without instability issues due to their reduced

cross-coupled stiffnesses - free tilting motion of pads supported on flexure

pivots. FPTPBs offer much less friction in pivot due to their integral

manufacturing utilizing wire EDM. Conventional tilting-pad bearings have major

drawbacks with pivot and pad wear due to relative motion of parts. Compared

with traditional gas bearings including three-lobe bearings and Rayleigh-step

bearings, FPTPBs are more complex in structure and more expensive; however,

their predictable rotordynamic performance and superior stability behavior at

high operating speeds provide them with desirable applications in oil-free

high-speed microturbomachinery.

Current research relates to the identification of dynamic damping

and stiffness coefficients for the bearings. The major tasks are:

(1) Complete measurements of rotor response for increasing

imbalances and compare to predictions from computational models.

(2) With e-relay deliver impact loads into test rig, measure the

rotor transient response and identify bearing damping and stiffness

coefficients from the displacements and forces derived from test results.

(3) Modify predictive code to include flow model for choked flow

through orifices.

(4) Envision, design and implement modifications to the current

test rig for future work.

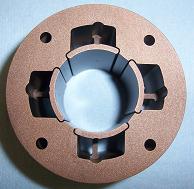

Test Rig Facility

& test Bearings

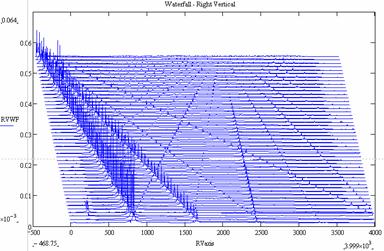

Measured rotor synchronous

response and waterfall plot:

2005 Status: Small 100 krpm test rig continues to provide superb test

data. Rotordynamic measurements conducted with Rayleigh-step gas bearings

coated with Argonne‘s NFC (Near Frictionless Carbon) demonstrated the bearings’

poor static load performance and worse rotordynamic response with severe sub

synchronous instabilities at low shaft speeds. The bearings could not operate

at speeds above 20 krpm. This speed is too low when considering that flexure

pivot hybrid bearings achieved 100 krpm without instability problems.

Current work: Hybrid Tilting Pad Gas Bearings: Analysis and

Tests

Gas

film bearings offer unique advantages enabling successful deployment of high-speed

oil-free turbomachinery. Current applications encompass micro power generators,

air cycle machines and turbo expanders. The investigation will continue to

advance the analysis and experimental validation of hybrid gas bearings with

static and dynamic force characteristics desirable in high-speed

turbomachinery.

Gas

film bearings offer unique advantages enabling successful deployment of high-speed

oil-free turbomachinery. Current applications encompass micro power generators,

air cycle machines and turbo expanders. The investigation will continue to

advance the analysis and experimental validation of hybrid gas bearings with

static and dynamic force characteristics desirable in high-speed

turbomachinery.

To date hybrid

(hydrostatic/hydrodynamic) flexure pivot-tilting pad bearings (FPTPBs) have

demonstrated superior static and dynamic forced performance than simple

three-lobe bearings and Rayleigh-step bearings tested earlier. FPTPBs are

mechanically complex and more expensive; however, their enhanced stability

characteristics and predictable rotordynamic performance, with verified

operation to speeds as high as 100 krpm, makes them desirable for the

envisioned oil-free applications in high speed micro turbomachinery.

The main objective is to advance the technology of gas film

bearings for applications to oil-free turbomachinery by demonstrating their rotordynamic

performance, reliability and durability. The tasks to be performed are:

a)

To

displace the rig to a vertical configuration and to measure the

synchronous response and stability of the test rotor on flexure-pivot pad gas

bearings. Stiffness and damping coefficients will be determined from measured

frequency domain transfer functions (load/displacement).

b)

To

assess the effect of solid lubricants, namely NFC and DLC coatings, on early

rotor lift-off and touchdown speeds, and to evaluate friction and wear on rotor

and bearing surfaces.

c)

Enhance

a computational code by including the hydrostatic pressurization to predict the

static and dynamic forced performance of externally pressurized gas bearings.

d)

To

validate predictive model with comparisons to experimental values.

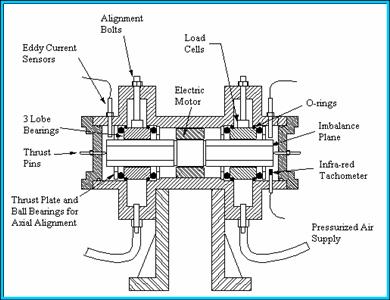

TEST RIG FACILITY

Max speed = 100 krpm, rotor diameter=29 mm, weight=0.87 kg

Measured response

of rotor supported on tilting pad gas bearings – Stable to 100 krpm

VIRTUAL TOUR

To be included 15

sec video clip

è Summary on computational analyses of gas bearings (past

research)

è To learn more,

order/read our PUBLICATIONS

Micro-turbomachinery (MTM) implements gas

bearings in compact units of enhanced mechanical reliability. Gas bearings,

however, have little damping and are prone to wear during frequent rotor

start-up and shut down conditions. Externally pressurized gas bearings provide

a simple solution to overcome excessive drag and allowing rub-free operation during

transient response events. Some commercial MTM currently implements gas foil

bearings, a costly proprietary technology with few, if any, proven reliable

predictive design models. The thrust of this research is to investigate

conventional bearings of low cost, easy to manufacture (common materials) and

easy to install and align.

Flexure pivot tilting pad bearings offer

little or no cross-coupled stiffness with enhanced rotordynamic stability.

These bearings, modified for hydrostatic pressurization, demonstrated superior

rotordynamic performance over other simple gas bearing configurations. The test

rig comprises of a rigid rotor, 0.825 kg and 28.6 mm in diameter, supported on

two hybrid flexure pivot hybrid gas bearings, each with four pads and 60% pivot

offset and 0.6 mm feeding holes. Experimental results show that external

pressurization stiffens the gas bearings, increasing the system critical speed

while reducing the modal damping. Most importantly, the tests demonstrate that

external pressurization is not needed for super critical speed operation. In

practice, the supply pressure could be shut off at high speeds with substantial

savings in operational efficiency. In addition, controlling the feed pressure

while the rotor passes through its critical speeds can eliminate high amplitude

motions because of the bearings’ inherent little damping.

The test rig integrates an inexpensive

automatic air pressure regulator to control the supply pressure into the gas

bearings. The measured system dynamic response determines the regulator control

scheme with a programmed schedule over a rotor speed region enclosing the

system critical speeds. Rotor speed coast-down tests with controlled supply

pressure into the bearings demonstrate the effective elimination of large rotor

motion amplitudes while crossing the system critical speeds. The simple on-off

supply pressure control, i.e. a sudden increase in pressure while approaching a

critical speed, is the best since it changes abruptly the bearing stiffness

coefficients and moves the system critical speed to a higher speed.

A rotordynamic analysis, integrating

bearing force coefficients predicted by an existing TRC computational model,

forwards critical speeds in agreement with the test results. Predicted rotor synchronous

responses for the cases with controlled supply show an excellent correlation

with the measured responses. The experiments validate the predictive tools and

demonstrate the controllable rotordynamic characteristics of the flexure pivot

hybrid gas bearings.