Metal Mesh Foil

Bearings for Oil-Free Turbomachinery

MAJOR APPLICATION: Cost effective gas foil bearing technology for high speed

oil-free turbomachinery

Sponsor: Turbomachinery Research Consortium

(07-11) , hardware donated by Honeywell Turbocharging Systems

Objective: To evaluate performance of metal-mesh foil

bearings for automotive turbochargers.

Significance:

High temperature, high speed oil-free

rotating machinery needs of a proven low friction bearing technology to give

adequate load support (stiffness) and with enough damping to limit rotor

synchronous responses and avoidance of rotordynamic instability. Gas foil bearings are a reliable and proven

technology, albeit too costly. The

present research aims to replace the foil structures with a cost effective,

metal mesh structure for use in automotive turbochargers. Prior experiments

conducted at Turbomachinery Laboratory demonstrate metal meshes have a superior

damping performance at high temperatures and in an oil free environment in

comparison with squeeze film dampers.

More details from Turbo Expo Paper

GT2009-59315, “Measurements of Structural Stiffness and Damping

Coefficients in a Metal Mesh Foil Bearing”

Test MMFB & Experimental FacilitY

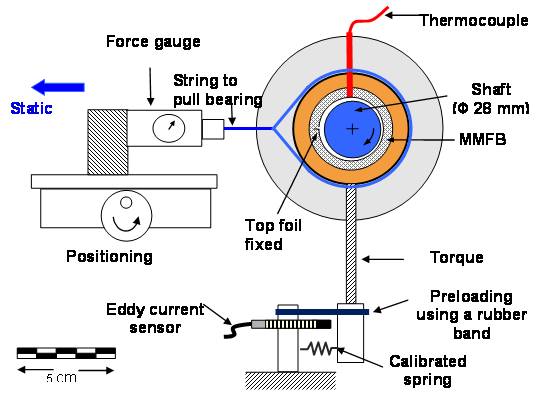

Figure 1 shows a schematic representation

of a metal mesh foil bearing.

Figure 1 Schematic representation of

a Metal mesh-foil bearing

Figure 2 shows

the photograph of a prototype bearing. The MMFBs employ commercially available

ring shaped metal mesh as the elastic support under a thin top foil. The

prototype bearing uses a metal mesh ring made of copper wires, owing to the large

structural damping offered by copper meshes . The top foil, a smooth arcuate

surface 127µm thick, is in contact with the journal when not in operation. Note

that, at high rotor speed operation, a thin hydrodynamic air film separates the

top foil and the rotating journal. Hence, any wear of the journal or the

bearing is absent while the rotor is airborne.

Figure 2 Metal mesh-foil bearing

prototype

Honeywell Turbo

Technologies donated two ball bearing turbochargers (TC), series T25, for this

TRC funded project. The TC unit does not have a compressor but a stub shaft, 5

mm in diameter and 35 mm in length, to hold a miniature test journal. The compressor impeller and volute of the

original TC are removed to expose the overhanging shaft. A journal of diameter

28 mm and length 55 mm is press fitted on the TC shaft end and fastened with a

nut.

Figure 3 shows a

schematic front view of the test bearing, journal, and the devices for

measurement of torque, applied load and temperature.

Figure 3 Metal mesh-foil bearing

test setup for measuring drag torque

More details from AHS conference paper, “Measurements

of Drag Torque, Lift-Off Speed and Temperature in a Metal Mesh Foil Bearing”

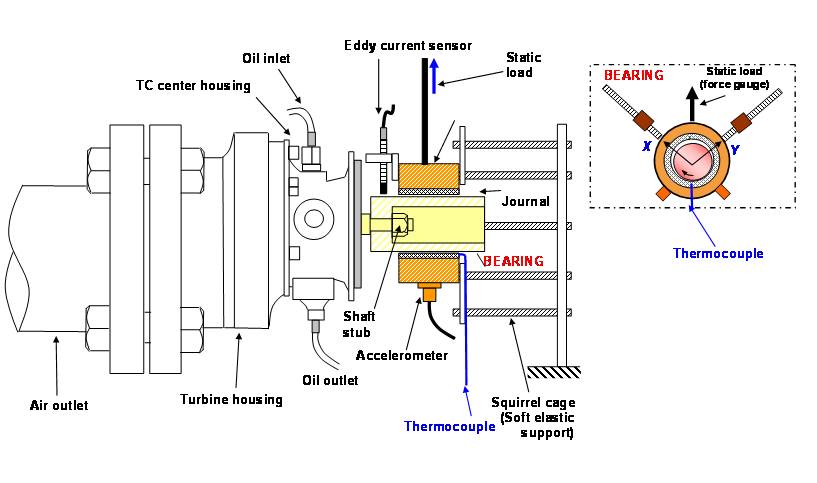

Figure 4 shows a schematic view of the test rig for identifying the bearing rotordynamic force coefficients.

Figure 4 Schematic view of MMFB mounted on shaft of turbocharger drive system. Inset

shows two stingers for application of dynamic loads along two orthogonal

directions

2008-10 work:

Figure 5 shows the journal speed and

bearing drag torque versus time during a lift-off test cycle with an applied static

(pull) load of 17.8 N (4 lb). The rotor accelerates beyond the bearing

lift of speed (~ 28 krpm) to a steady speed of 65 kprm, and then decelerated to

rest. As the rotor starts to spin, rubbing between the journal and top foil

surfaces generate a sharp peak in bearing torque (~ 110 N-mm). Once the journal

starts rotating, the torque falls rapidly. Further, the bearing operates in a

mixed lubrication regime with partial asperity contacts, until the thin air

film completely separates the two surfaces. The airborne journal, at a steady

speed of 65 kprm, offers a significantly smaller drag torque of ~ 3.2 N-mm,

i.e. 3% of the peak (break-up) torque. While decelerating to rest, the journal

comes into physical contact with the top foil and causes a sharp peak in the

drag torque (80 N-mm).

Figure 5 Rotor speed and bearing torque versus time during a lift-off

test cycle for applied static load of 17.8 N (4 lb). Manual speed-up to 65

krpm, operation at a constant rotor speed of 65 krpm, and deceleration to rest

Figure 6 shows the

bearing drag torque versus rotor speed, during rotor speedup, for increasing

static loads of 9.6 N, 18.2 N, 26.9 N and 35.8 N. Note that the uncertainty in

drag torque is ± 0.35N-mm for drag torque < 10 N-mm. For each static load, as

the rotor speed increases, initially the bearing drag torque decreases quickly

and, when the journal is airborne, increases gradually with rotor speed.

Figure 6 Bearing drag torque versus rotor speed for increasing static

loads. Measurement during rotor speed-up tests

Figure 7 show that the friction coefficient

f changes only slightly

with rotor speed after the rotor is airborne, i.e. once the MMFB operates with

a hydrodynamic film. The identified f is the lowest for the largest

applied load of 35.8 N. Owing to the very low friction coefficient, f ~0.01 to 0.02 (when the bearing is

airborne), the drag power losses in the bearing are rather small. For example,

at 60 krpm and the highest static load, the estimated power loss, P=Torque x Ω ~ 4 N-mm x

60000 (π/30) = 25.1 W.

Fig. 7 Bearing drag torque versus rotor speed for increasing static

loads. Measurement during rotor speed-up tests

More details from Turbo Expo 2010 conference paper, “ Identification of

Rotordynamic Force Coefficients of a Metal Mesh Foil Bearing Using Impact Load

Excitations”

2010 work:

Estimation of Rotordynamic Stiffness, Equivalent Viscous Damping and Loss

Factor

Figure 8 Photograph of gas bearing

test rig for dynamic load excitations

Figure 9 Close-up view of metal mesh

foil bearing and connections to shakers for dynamic load excitation

2011-12 work: Analytical Modeling and prediction of MMFB Rotordynamic Performance

Updated : Jan 21, 2011