Thrust

Collars for Integrally Geared Compressors

MAJOR APPLICATION: Cost effective axial load

support in rotating machinery (typically integrally geared compressors)

Sponsor: Samsung Techwin

(2012-2014)

OBJECTIVE: To evaluate the hydrodynamic

pressure and force coefficients in the thin film between the thrust collar and

bull gear taper.

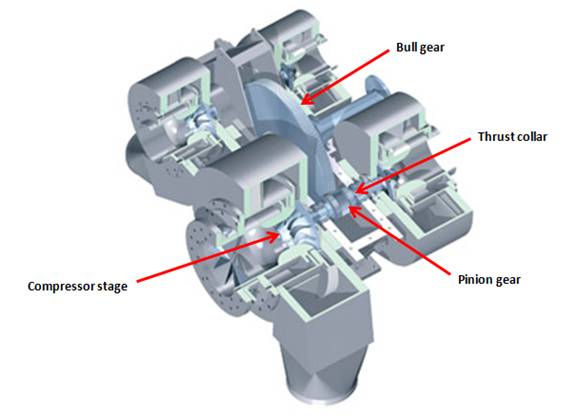

Significance: Typically thrust collars are

implemented in integrally geared compressors to absorb the axial load on the

pinion shaft (see Fig. 1). This provides a cost effective and efficient means

of balancing the thrust load created by the compressor or expander stages on

either side of the pinion gear. These thrust collars (sometimes referred to as rider rings) act as hydrodynamic

bearings transferring the axial load to the bull gear shaft, on which there is

a large diameter thrust bearing to absorb the thrust in the compressor.

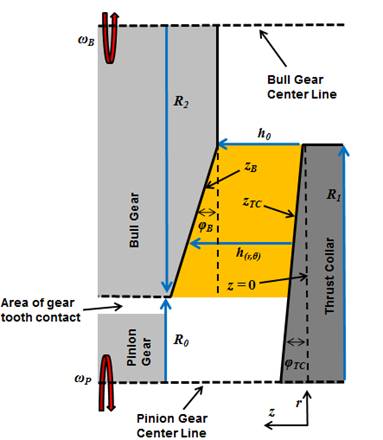

Fig. 2 shows a top view of the

lubricated zone between the thrust collar and the bull gear. The lubricant in

this region develops hydrodynamic pressure, governed by Reynolds equation. The

thin film also has associated force coefficients (stiffness and damping).

Fig

1. Cut view of a four stage integrally geared

compressor.

Fig. 2. Schematic

view of the fluid film between the bull gear taper and the thrust collar.