Computational Fluid Dynamics (CFD) Analysis for Liquid/Gas Seals

Sponsor:

1. Torishima

Pump Co. Ltd. (2015-2016),

2.

Texas A&M University Turbomachinery Research

Consortium (TRC, 2016-2019)

To

advance CFD models of annular seals and to develop hybrid (CFD ŕ bulk flow model) quick predictive

tools.

Resources:

1.

ANSYS® Fluent®, CFX®;

2.

TAMU High-Performance Computing Center access

Ada: 852 Nodes (17,340 total cores)

Tera: 320 Nodes (9,632 total cores)

Curie: 48Nodes (800 total cores)

LONESTAR 5: 1252 Nodes (30,048 total cores)

3.

TAMU Turbomachinery Laboratory Clusters (bigmo &

DWC).

TOPICS

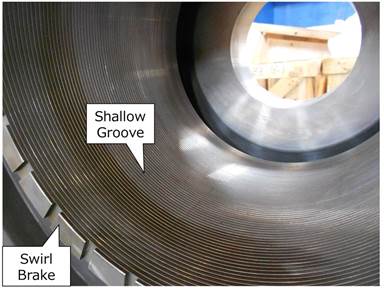

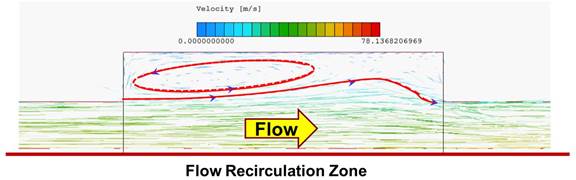

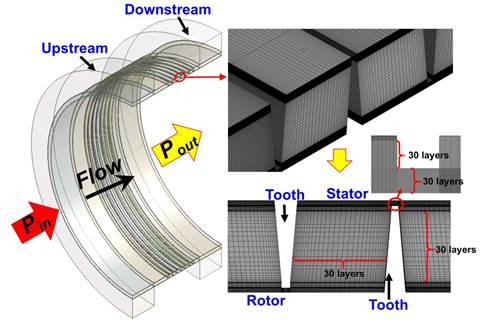

Pump Grooved Seals (Liquid)

CFD predicted seal

reaction force

Gas Labyrinth Seals

CFD model for gas

labyrinth seals

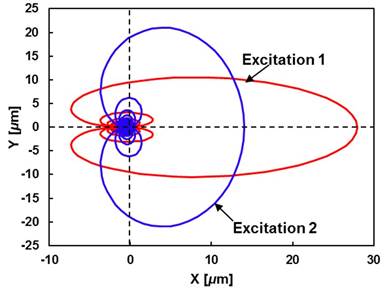

Rotor multi-frequency

excitation motion for gas labyrinth seals analysis

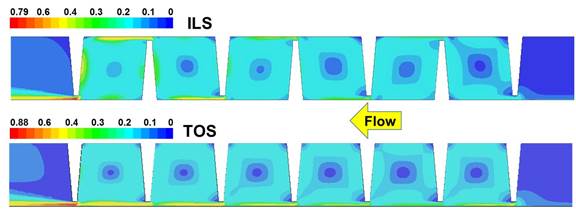

Flow Mach number

contour comparison between the all-Teeth-On-Stator (TOS) labyrinth seal and the

Interlocking-Labyrinth-Seal (ILS)

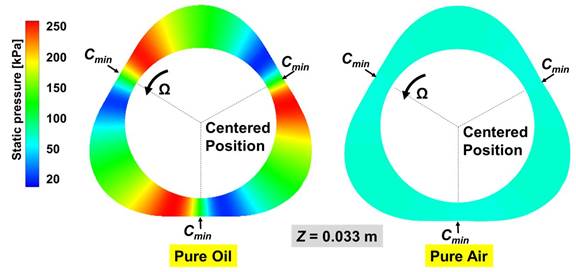

Three Wave Seals for Submersible Subsea

Pumps

Pressure field comparison

between the pure oil and pure air operating conditions

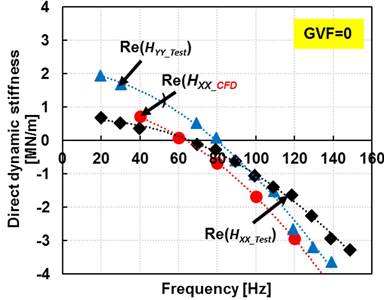

Comparison of the

direct dynamic stiffness coefficient between the CFD predictions and the test

measurements.

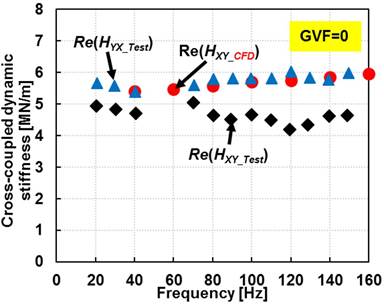

Comparison of the

cross-coupled dynamic stiffness coefficient between the CFD predictions and the

test measurements.

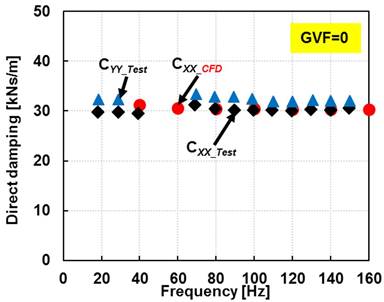

Comparison of the

direct damping coefficient between the CFD predictions and the test

measurements.

Publication ŕ Learn more:

1.

Wu, T., and San Andres, L., 2018, “Gas Labyrinth Seals: On

the Effect of Clearance and Operating Conditions on Wall Friction Factors – a

CFD Investigation,” Tribology

International, 131, pp. 363-376.

2.

San Andres, L. and Wu, T., Barajas-Rivera, J., Zhang, J.,

and Kawashita, R., 2019, “Leakage and Cavity

Pressures in an Interlocking Labyrinth Gas Seal: Measurements vs. Predictions,”

ASME Turbo-Expo 2019, Paper No. GT2019-91507 (Recommended for journal publication by the Review Committee)

3.

Lu, X., San Andres, L. and Wu, T., 2019, “Leakage and

Dynamic Forced Performance of A Grooved Wet (Bubbly Liquid) Seal,” ASME

Turbo-Expo 2019, Paper No. GT2019-90254 (Recommended

for Journal publication by the Review Committee)

4.

Wu, T., and San Andres, L., 2019, “Pump Grooved Seals: a CFD

Approach to Improve Bulk-Flow Model Predictions,” ASME Turbo-Expo 2019, Paper

No. GT2019-90499. (Recommended for

Journal publication by the Review Committee)

5.

San Andres, L. Lu, X., and Wu, T., 2019, “On The Influence

of Gas Content on the Rotordynamic Force Coefficients of a Three-Wave (Air in

Oil) Annular Seal for Multiple Phase Pumps,” ASME-JSME-KSME Joint Fluids

Engineering Conference, July 28- August 1, San Francisco, CA, USA.

6.

Wu, T., and San Andres, L., 2018, “Leakage and Dynamic Force

Coefficients for Two Labyrinth Gas Seals: Teeth-on-Stator and Interlocking

Configurations. A CFD approach to their Performance,” Journal of Engineering for Gas Turbine and Power, 141(4), pp. 04250101-04250112.

7.

San Andres, L., Wu, T., Maeda, H. and Ono, T., 2017 “A

Computational Fluid Dynamics (CFD) Modified Bulk-Flow Analysis for

Circumferentially Shallow Grooved Liquid Seals,” Journal of Engineering for Gas Turbine and Power, 140(1), pp. 0125041-0125049.

Original by Tingcheng Wu (January 2019)