Computational Fluid Dynamics (CFD) Analysis for Wet Gas and

Bubbly Liquid Seals

* Wet gas: has up to 5% liquid volume fraction.

On how millions of nodes and equations

can be useful to learn more about the operation of mechanical elements. CFD

supported by extensive test data.

Who said more is not better?

The work: more number crunching to crunch more learning!

Publications

1.

Yang,

J., and San Andrés, L., 2022, “Making Better Swirl Brakes Using Computational

Fluid Dynamics: Performance Enhancement From Geometry

Variation,” ASME J. Eng. Gas Turbines Power, Vol. 144(2): 021027, https://doi.org/10.1115/1.4051962 (ASME GT2021-58956).

2.

San

Andrés, L., and Yang, J., 2021,”An Analytical Two-Phase Flow Model for

Prediction of Leakage in Wet Gas Labyrinth Seals and Pocket Damper Seals. Is

Simplicity Still Desired?” ASME J. Eng. Gas Turbines Power, Vol. 143(12): 121016, https://doi.org/10.1115/1.4051916

(ASME GT2021-58958).

3.

Yang, J, San

Andrés, L., and, Lu, X., 2019, “Leakage and Dynamic Force Coefficients

of a Pocket Damper Seal Operating Under a Wet Gas condition: Tests vs.

Predictions,” ASME J. Eng. Gas Turbines Power, Vol. 141(11):111001, DOI:

10.1115/1.4044307 (ASME

GT2019-90331)..

4.

Yang, J., and San Andrés, L., 2019, “On

the Influence of the Entrance Section on the Rotordynamic Performance of a Pump

Seal with Uniform Clearance: a Sharp Edge VS. a Round

Inlet,” ASME J. Eng. Gas Turbines Power, 141(3),

pp. 031029. DOI: 10.1115/1.4040742 (ASME GT20018-75414)

5.

San Andrés, L., Yang, J., and Lu, X.,

2019, “On the Leakage, Torque and Dynamic Force Coefficients of an Air in Oil

(Wet) Annular Seal: a CFD Analysis Anchored to Test Data,” ASME J. Eng. Gas

Turbines Power, 141(2), pp. 021008. DOI:

10.1115/1.4040766 (ASME GT20018-77140)

6.

Yang, J., and

San Andrés, L., 2019, “On the Influence of the Entrance Section on the

Rotordynamic Performance of a Pump Seal with Uniform Clearance: a Sharp Edge

vs. a Round Inlet,” ASME J. Eng. Gas Turbines Power, Vol. 141(3), 032109, DOI: 10.1115/1.4040742

(ASME GT20018-75414)

7.

San Andrés,

L., Yang, J., and Xu, L., 2019, “On the Leakage, Torque and Dynamic Force

Coefficients of an Air in Oil (Wet) Annular Seal: a CFD Analysis Anchored to

Test Data,” ASME J. Eng. Gas Turbines Power, Vol. 141(2), 021008, DOI:

10.1115/1.4040766 (ASME GT20018-77140).

8.

San

Andrés, L., and Yang, J., 2018, “The Influence of Corner Shape on the Static and

Dynamic Performance on an Annular Pressure Seal,” Proc. Global Power and

Propulsion Society Forum 18, Zurich, Switzerland, 10-12 January 2018, Paper

GPPS-2018-55 (www.gpps.global )

Sponsors

1. Texas A&M University (TAMU) Turbomachinery Laboratory

(2016-2018).

2. TAMU Turbomachinery Research Consortium (TRC) (2017-2021).

Computational Resources TAMU High-Performance Computing Center &

TAMU Turbomachinery Laboratory Clusters

Research Background

è Cost efficient

subsea factories must rely on multiple-phase flow compression and pump systems

that reduce tieback systems and perform full flow separation on the sea floor.

è Operation

requirements of subsea turbomachinery: ~ 5% liquid volume fraction (LVF) in wet

compressors and up to ~ 90% gas volume fraction (GVF) in pumps.

è It is already

known that seals operating under a wet gas or bubbly flow conditions do affect

system rotordynamic stability.

Objective Sound Engineering to Quantify

the Leakage and Dynamic Forced Performance of Annular Seals under Wet Gas

Conditions!

Project I

Wet Gas

in a Smooth Annular Seal

To complement experimental work by revealing flow field

structures in multiple-phase flow seals through Computational Fluid Dynamics

(CFD) and to validate/update engineering (BFM) predictive tools.

Operating conditions

Supply

pressure: 1.0 ~ 3.5 bar(a); Rotor speed: 3500 rpm

(surface speed 23 m/s);

Inlet

gas volume fraction (GVF): 0, 0.2, 0.4, 0.6, 0.8, 0.9, 1.

Oil

density: 830 kg/m3 & viscosity: 8.2 cP

A Wet Smooth Surface Annular Seal

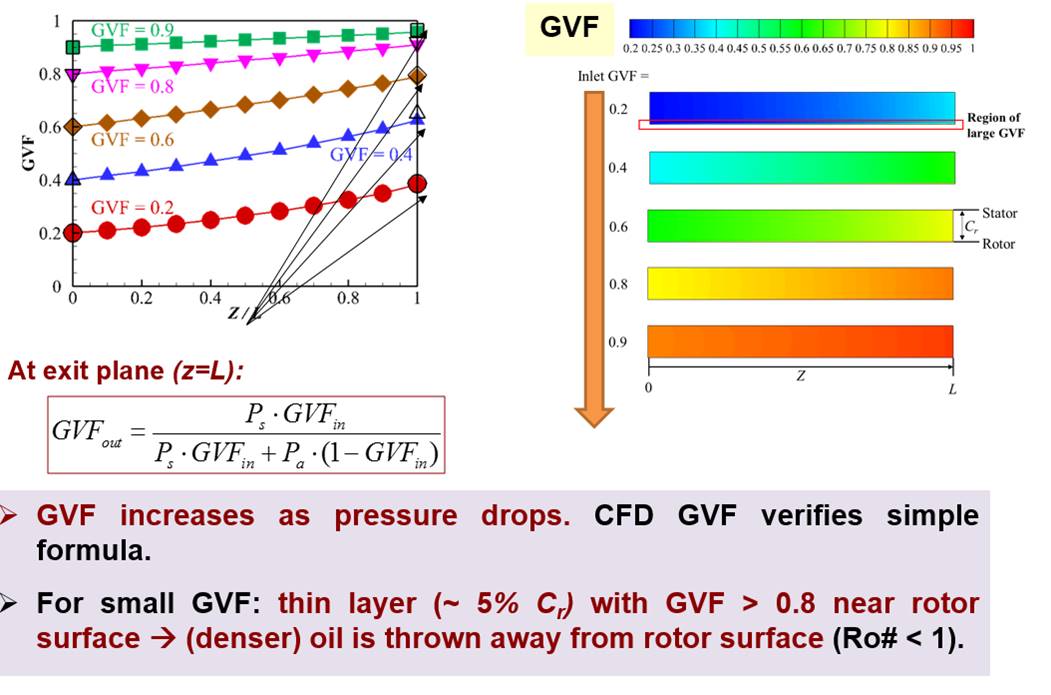

2D CFD Predicted Gas Volume Fraction (GVF) vs axial length

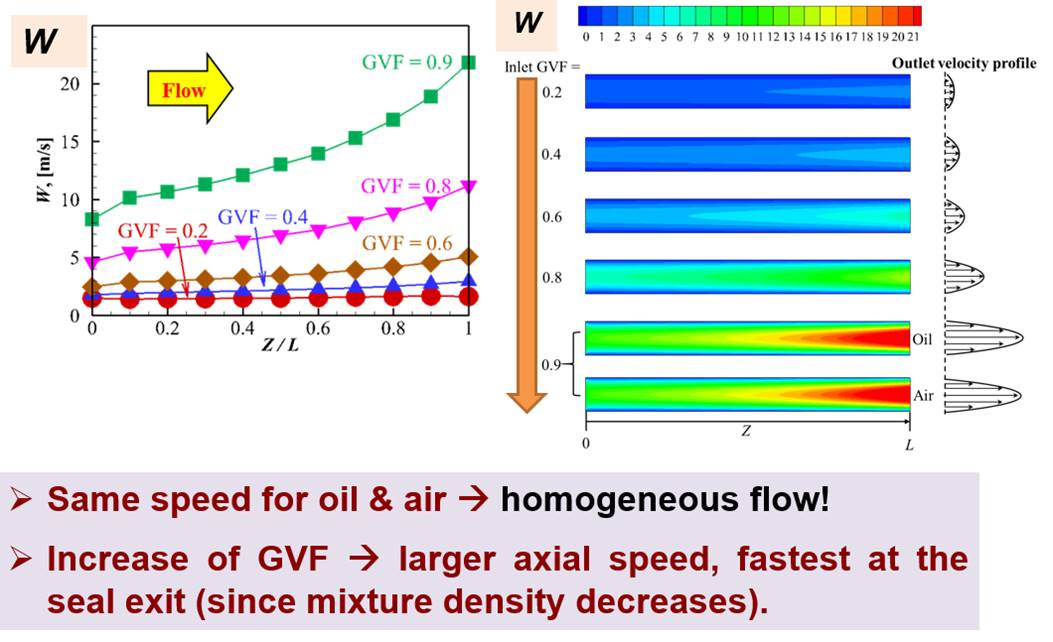

2D CFD Predicted Axial Velocity (W) vs axial length

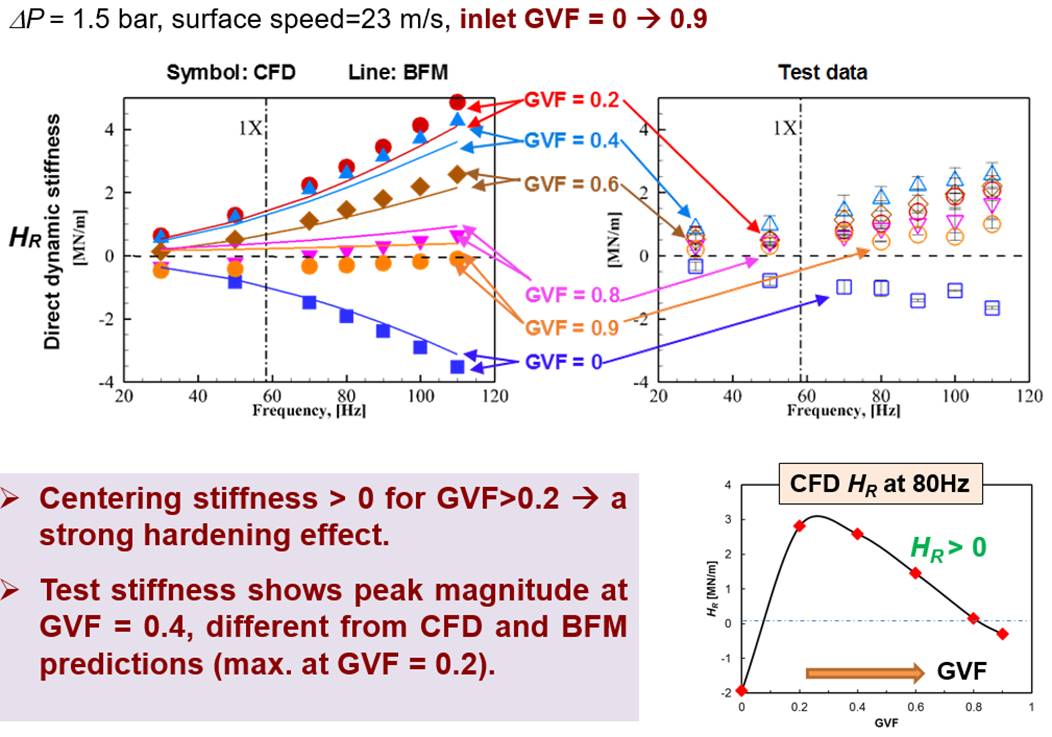

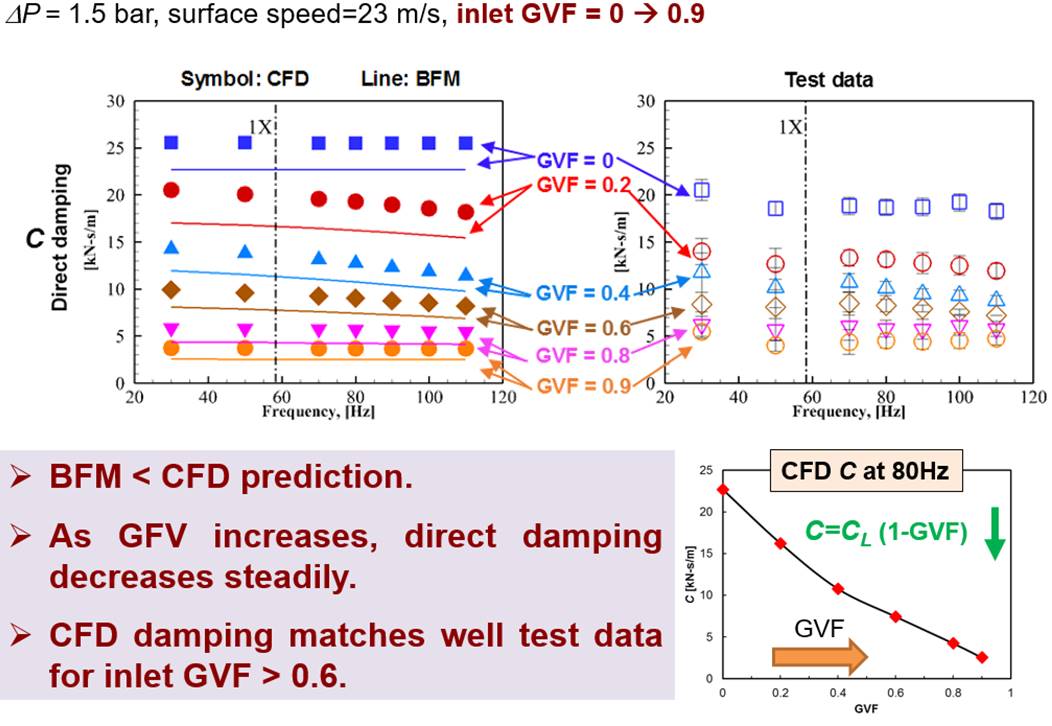

CFD Predicted Seal Direct Dynamic Stiffness against Test Data

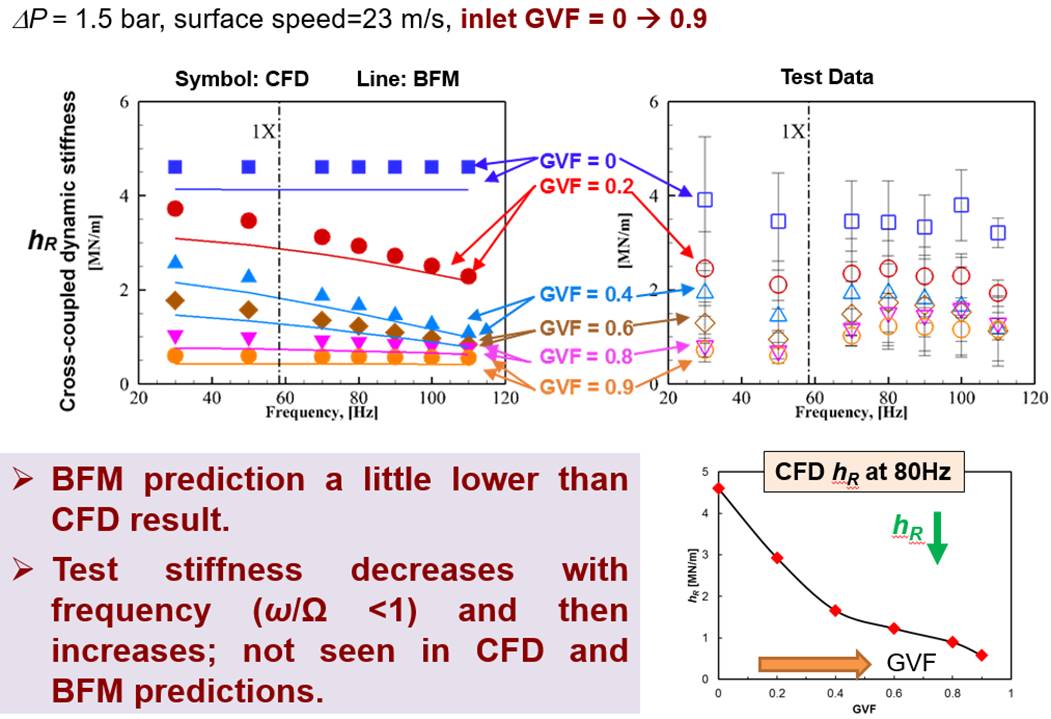

CFD Predicted Seal Cross-coupled Dynamic Stiffness against Test

Data

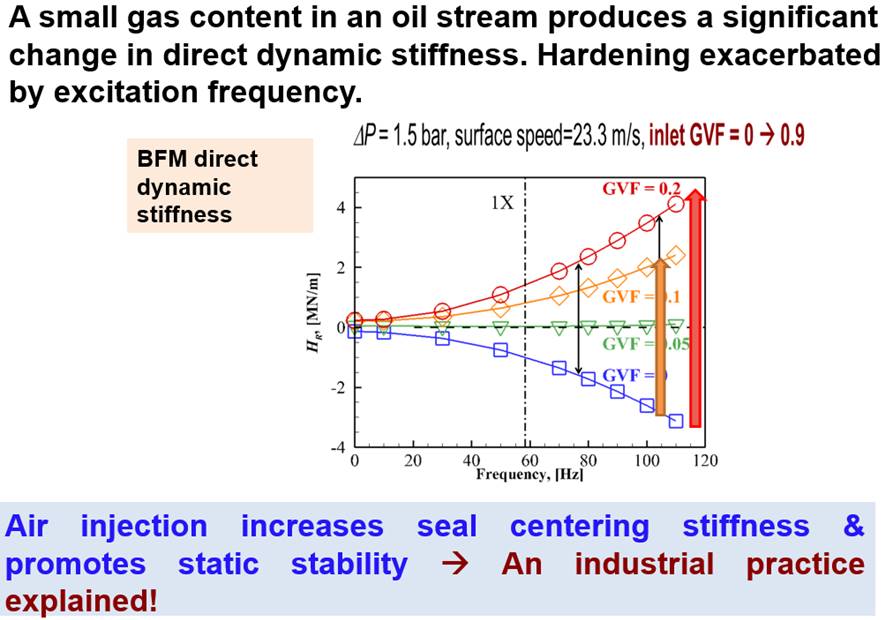

CFD Predicted Seal Direct damping against Test Data

Stiffness Hardening Effect

Conclusions

1. CFD predictions (leakage, power loss) agree with

test data, and also produce high fidelity flow field variables, including

pressure, speeds, and GVF.

2. Operation with a low GVF (< 0.4)

produces a significant hardening effect which makes positive the direct

stiffness. Test data shows same rapid stiffness increase as GVFà 0.2.

3. Stiffness hardening effect is due to

the dramatic reduction in sound speed brought by a small amount of gas (fluid

becomes more compressible).

4. The combination of test results and CFD

and BFM analyses furthers the engineering of seals for wet gas

compressors and bubbly liquids in multiple phase pumps.

Project II

Wet Gas

in a Pocket Damper Seal

Aim of the work

1. Experimentally and

numerically investigate the leakage and dynamic force coefficients of a fully

partitioned pocket damper seal, operating with just air (dry condition) and oil in air (wet

condition).

2. Apply CFD to showcase the flow fields in

pocket damper seal under a wet gas

condition.

Operating conditions

Supply

pressure: 1.0 ~ 3.2 bar(a); Rotor speed: 5250 rpm

(surface speed 35 m/s);

Inlet

liquid volume fraction (LVF): 0, 0.4%. Oil

density: 830 kg/m3 & viscosity 8.2 cP

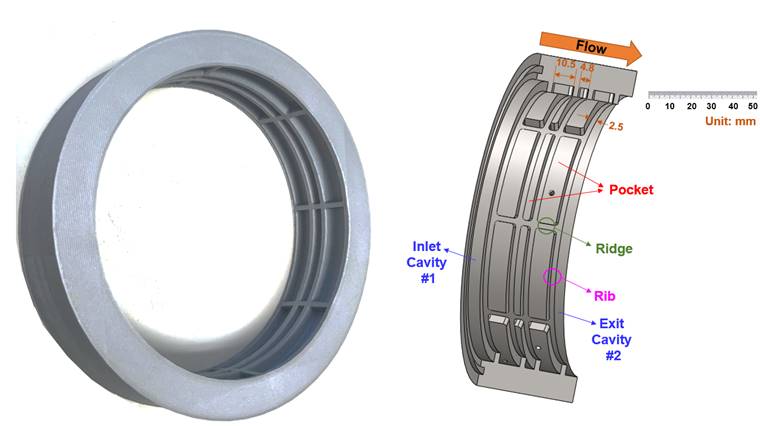

A Four-Rib, Eight-Pocket Damper Seal

3D Mesh for the Pocket Damper Seal

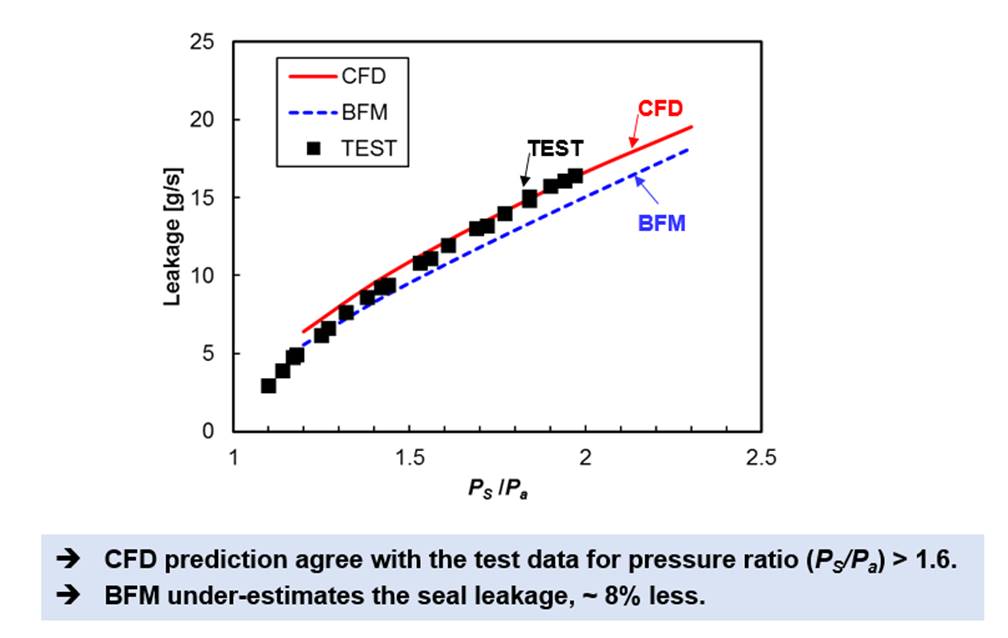

Test Measured, CFD Predicted and BFM Predicted Leakage for the

Pocket Damper Seal Operating with Air

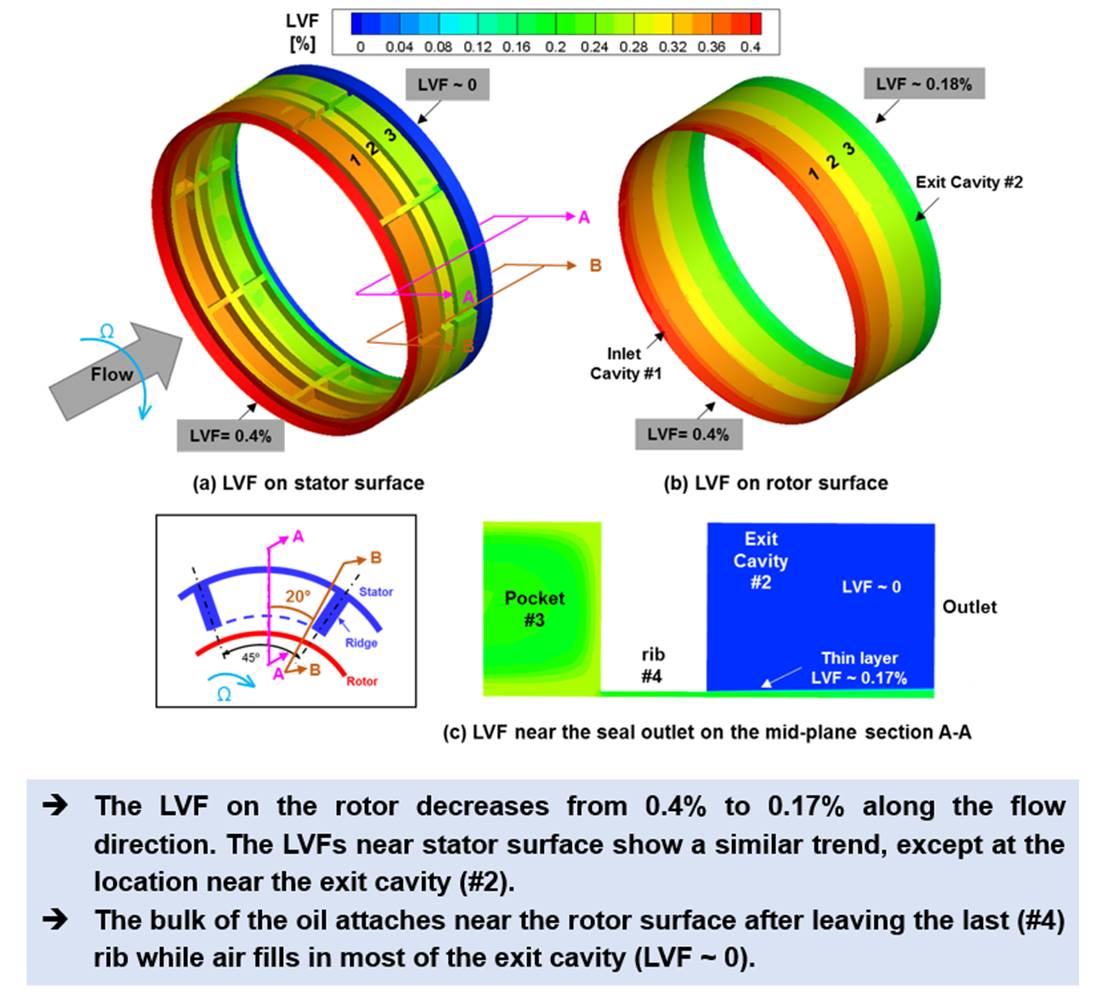

CFD Predicted Liquid Volume Fraction (LVF) Contours on Rotor and

Stator Surfaces (Wet Gas Pocket Damper Seal, inlet LVF = 0.4%)

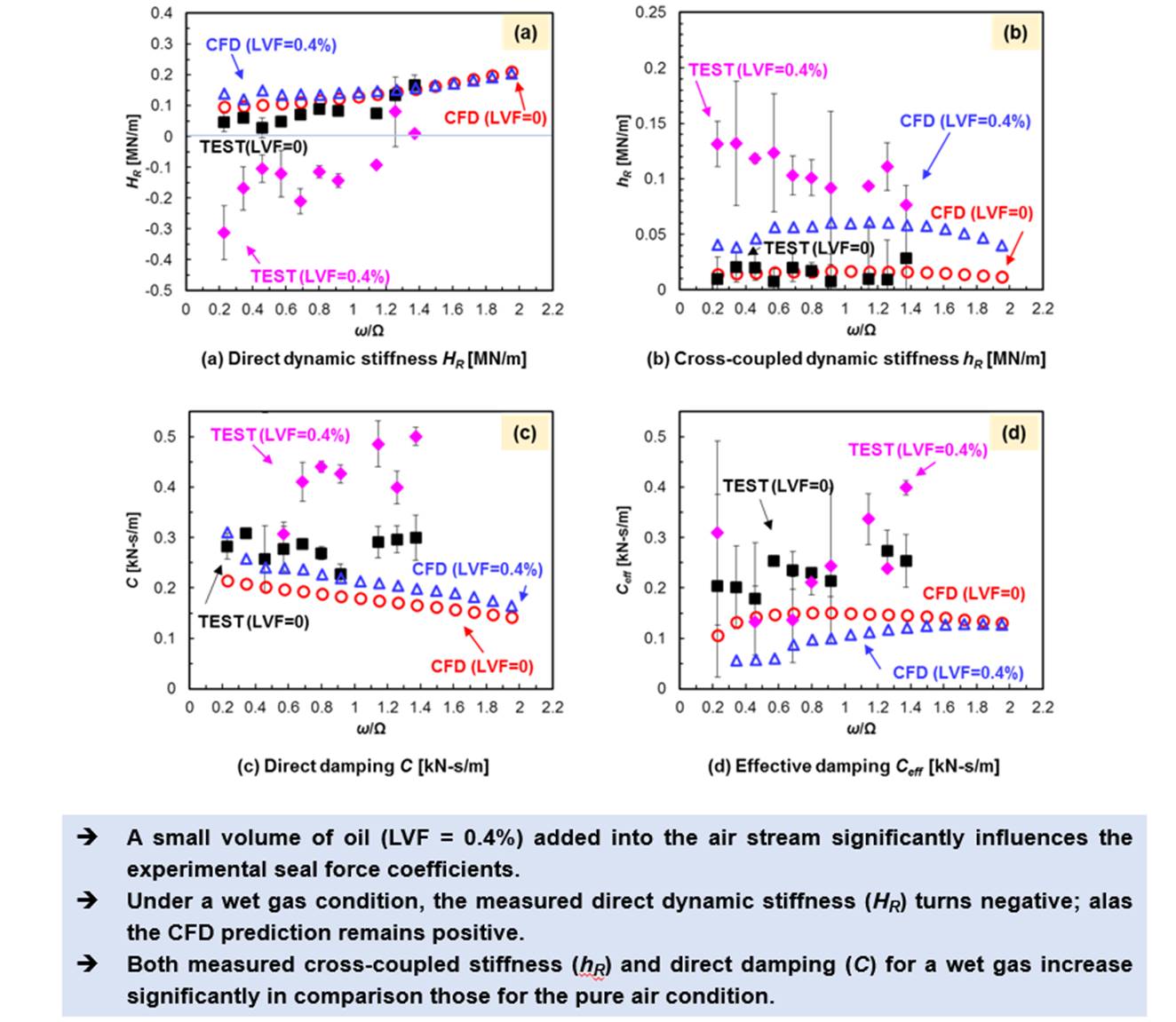

CFD Predicted Dynamic Force Coefficients against Test Data for

Gas Pocket Damper Seal and Wet Gas Pocket Damper Seal (inlet LVF = 0.4%)

Conclusions

1. For dry gas condition, the

measured mass flow rate nonlinearly increases with the inlet pressure. For

operation with a wet gas, the measured leakage increases rapidly as the

liquid density is much larger than that of the gas. CFD predictions match the

recorded leakage.

2. Under a dry gas condition, the experimental direct dynamic stiffness

(HR) increases with excitation frequency, whereas the

cross-coupled dynamic stiffness (hR)

is a minute fraction of HR and showing a high variability as

frequency increases. The test effective damping (Ceff)

is relatively constant as the excitation frequency (w) increases.

3. For a wet gas condition are with

inlet LVF=0.4%, the test derived force coefficients show a large variation

along the two orthogonal directions of forced excitation. The large liquid mass

fraction (57%) makes the dynamic direct stiffness HR negative

though decreasing in magnitude as the excitation frequency increases.

4.

The CFD model for wet gas operation delivers high fidelity

fields, such as pressure, liquid fraction and velocities, which demonstrate the

ridges in a pocket limit the development of the circumferential flow speed

while reducing the liquid content in the middle of a pocket.

Last update: August 11, 2022