XL_ThrustBearing®: A Computational Physics Analysis Tool for

Tilting Pad Thrust Bearings (both regular and self-equalizing types).

|

Sponsors: 1.

Texas

A&M Turbomachinery Laboratory (2016-2017), 2. Texas A&M University Turbomachinery Research Consortium

(TRC, 2017-2019) Goal: To

build a comprehensive computational tool for prediction of the static and

dynamic load performance of thrust bearings and further integrate it into

XLTRC2® software package. Resources: 1. XL_TRC2®. |

|

XL_ThrustBearing® Software tool

Features:

|

|

NEW in v

3.0,

|

Analysis

Output:

|

NEW in v

3.0,

|

- Along with 2D

and 3D graphs showing the operating characteristics, e.g. fluid film

thickness field, pressure field, fluid film temperature field, pad

deformation fields.

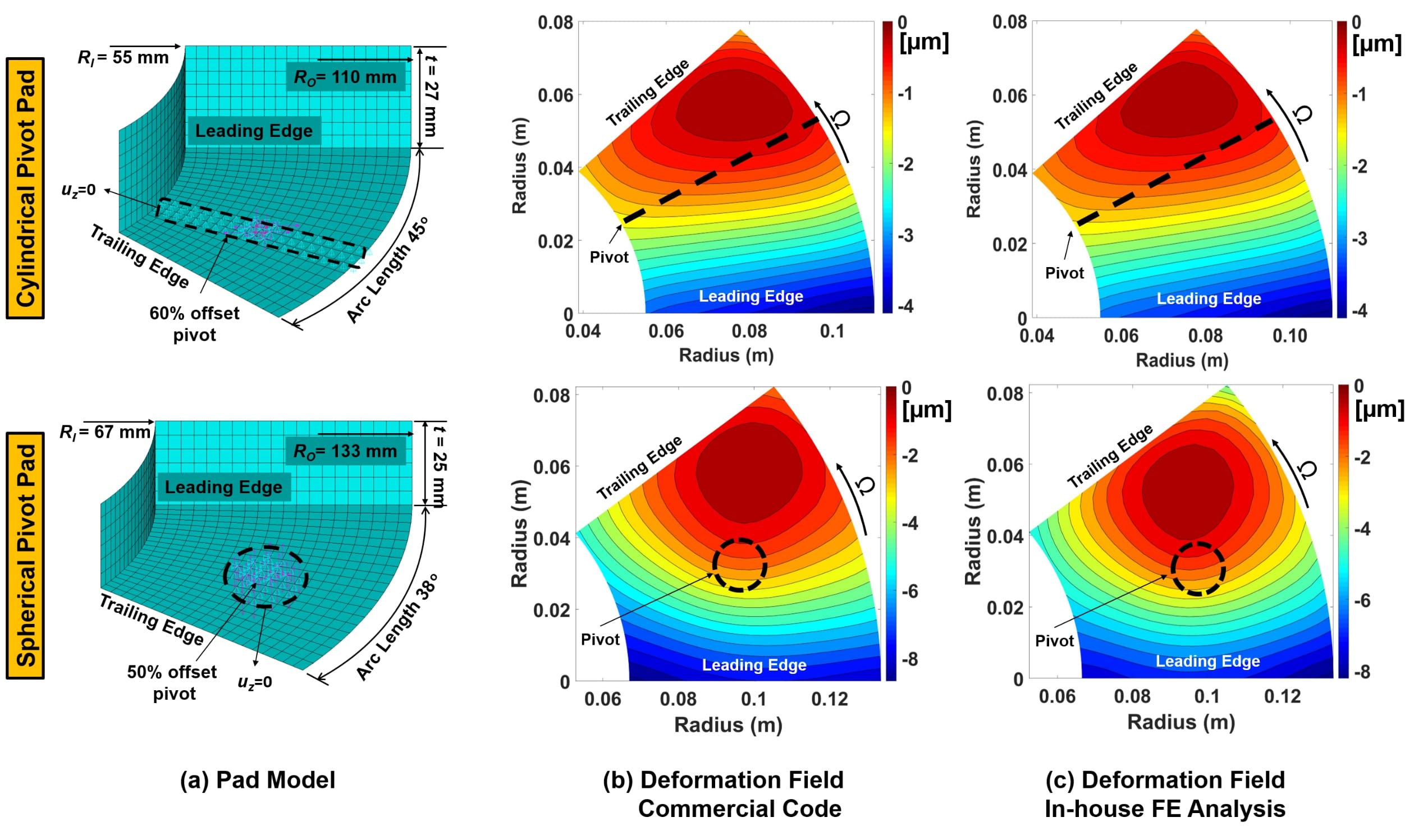

Validation of Predictions

Versus

Ansys®:

Predictions of pad top surface

elastic deformations for (top) a cylindrical pivot TPTB, and (bottom) a spherical

pivot TPTB. Comparison between commercial software and in-house FE model

(graphs in middle and right side). Supply temperature = 46°C, Rotor speed = 3 krpm and specific load = 1.0 MPa.

Versus Test

Data:

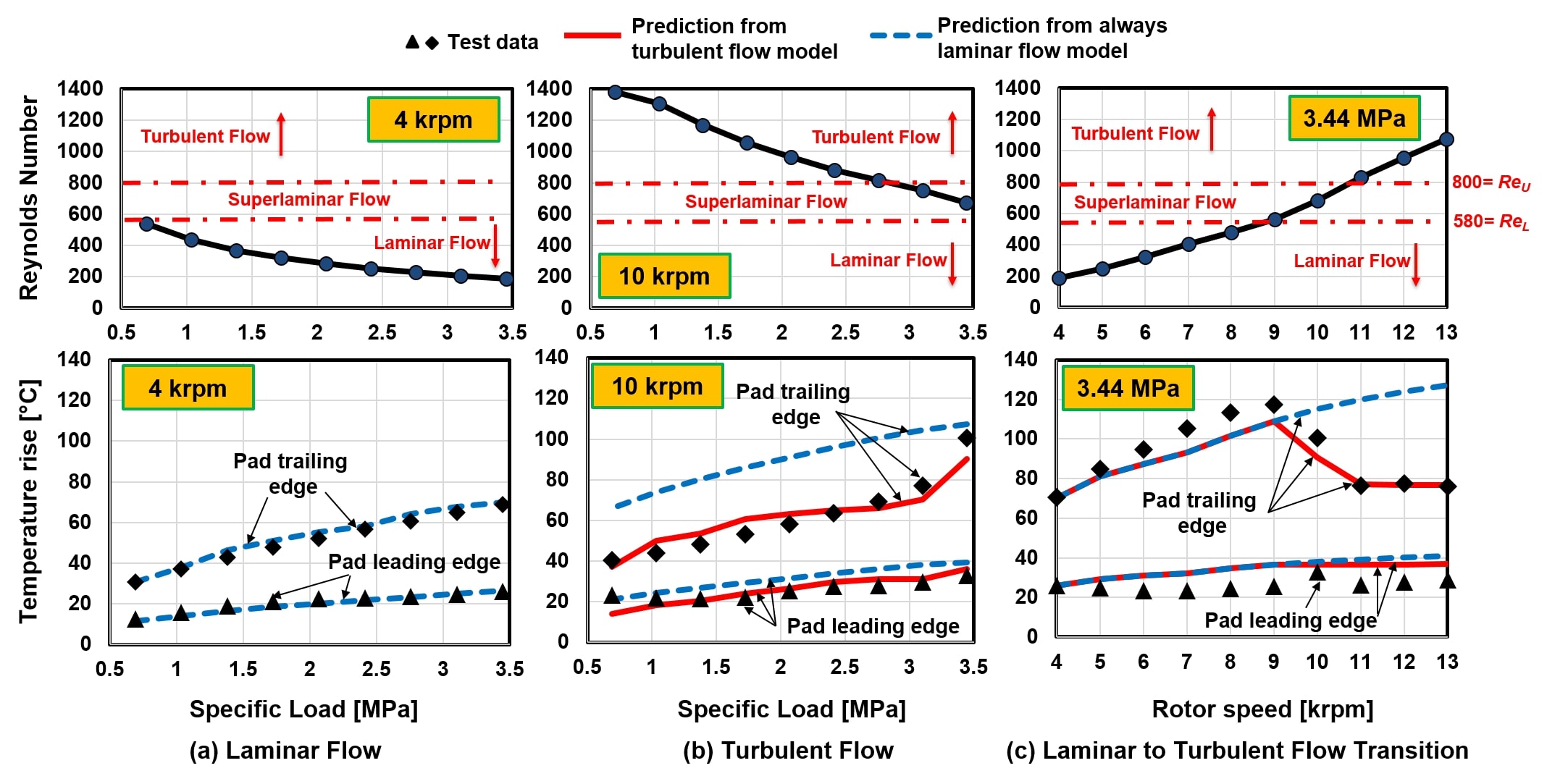

a)

Pad temperature rise

TEHD predicted pad subsurface

temperature rise derived from both a laminar flow model and a turbulent flow

model vs test data for a six-pad TPTB [30]. Supply temperature = 46°C.

|

b)

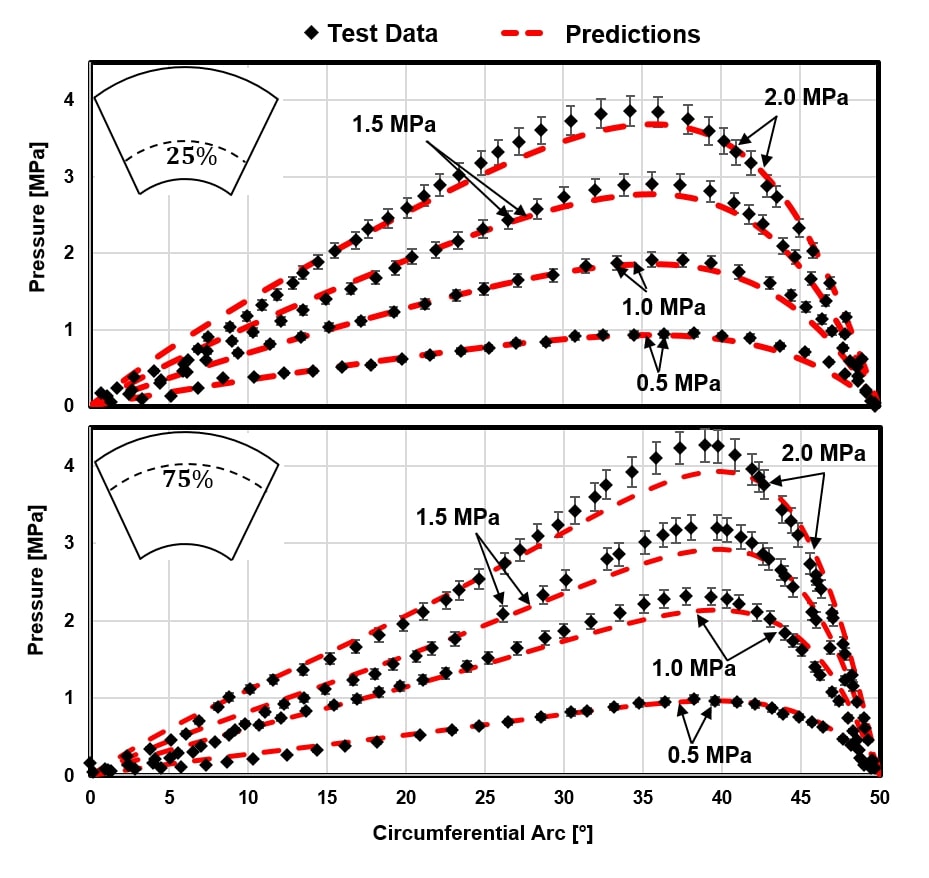

Pressure field

TEHD predicted oil film

pressure along the circumferential length of the pad at the 25% (top) and 75%

(bottom) of the radial length vs test data for a six-pad TPTB operating under

0.5, 1.0, 1.5, and 2.0 MPa of specific load per pad. Rotor speed = 3 krpm, supply temperature = 40 ˚C. |

c)

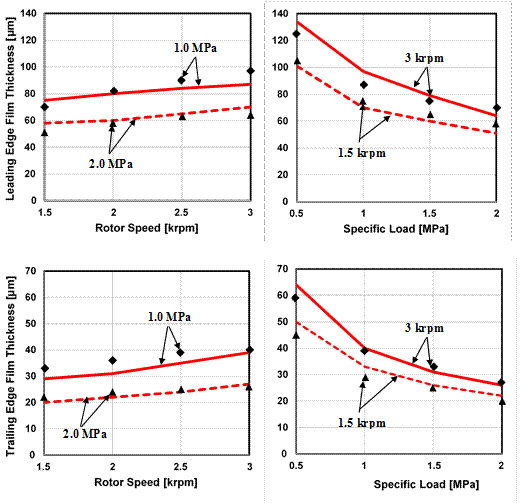

Film Thickness

TEHD predicted oil film

thickness at the mean radius of the pad leading edge (top) and trailing edge

(bottom) vs test data for a six-pad TPTB. Supply temperature = 40 ˚C. |

|

Further Predictions from XL_ThrustBearing® for an Example Self-Equalizing

Tilting Pad Thrust Bearing

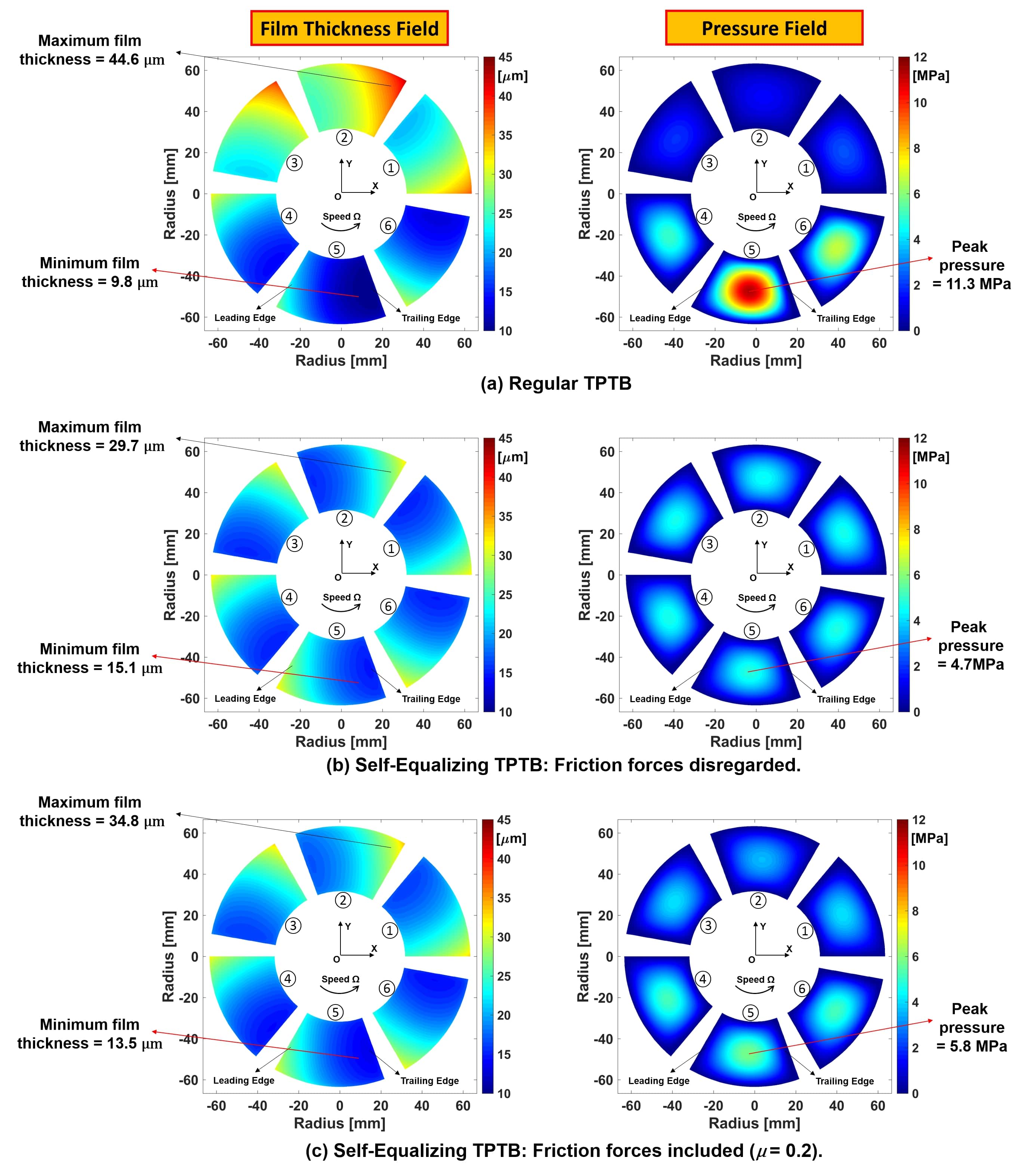

Predicted fluid film thickness

field (left) and pressure field (right) for a TPTB of (a) regular type, (b)

self-equalizing type without including contact friction forces, and (c)

self-equaling type with contact friction forces included. Bearing operates with

0.01° thrust collar (static) misalignment. Rotor speed = 4krpm, specific load

per pad = 2 MPa, µ= 0.2.

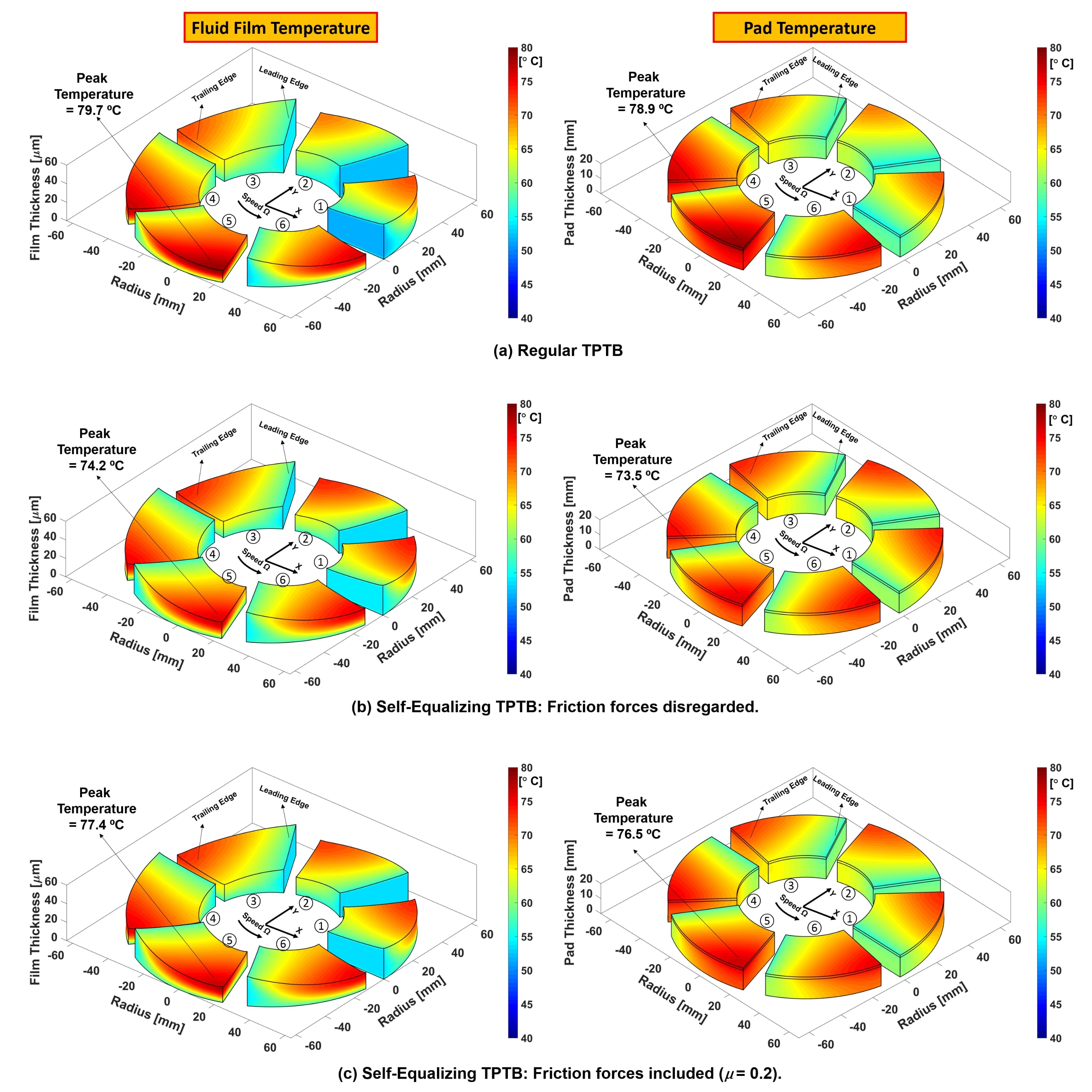

Predicted fluid film temperature

field (left) and pad temperature field (right) for a TPTB of (a) regular type,

(b) self-equalizing type without including contact friction forces, and (c)

self-equaling type with contact friction forces included. Bearing operates with

0.01° thrust collar (static) misalignment. Rotor speed = 4krpm, specific load

per pad = 2 MPa, µ=0.2.

Predicted fluid film temperature

field (left) and pad temperature field (right) for a TPTB of (a) regular type,

(b) self-equalizing type without including contact friction forces, and (c)

self-equaling type with contact friction forces included. Bearing operates with

0.01° thrust collar (static) misalignment. Rotor speed = 4krpm, specific load

per pad = 2 MPa, µ= 0.2.

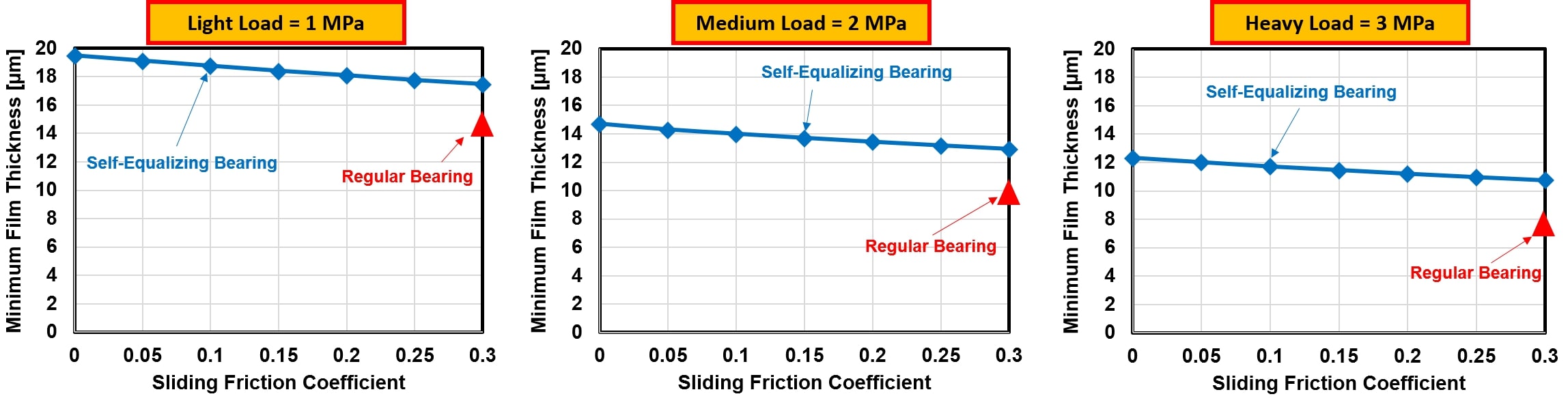

Predicted pad minimum fluid film

thickness for self-equalizing TPTB operating under light to heavy applied loads

vs sliding friction coefficient. Bearing operates with 0.01° thrust collar

(static) misalignment. Applied load per pad = 1 MPa to 3 MPa and rotor speed =

4krpm.

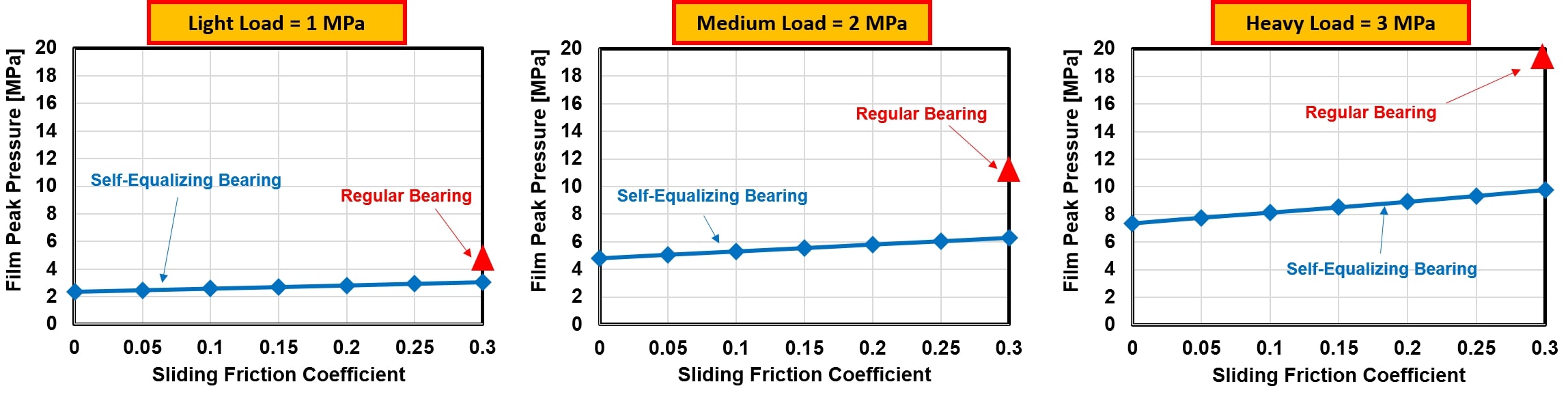

Predicted fluid film pressure on

a pad for self-equalizing TPTB operating under light to heavy applied loads vs

sliding friction coefficient. Bearing operates with 0.01° thrust collar

(static) misalignment. Applied load per pad = 1 MPa to 3 MPa and rotor speed =

4krpm.

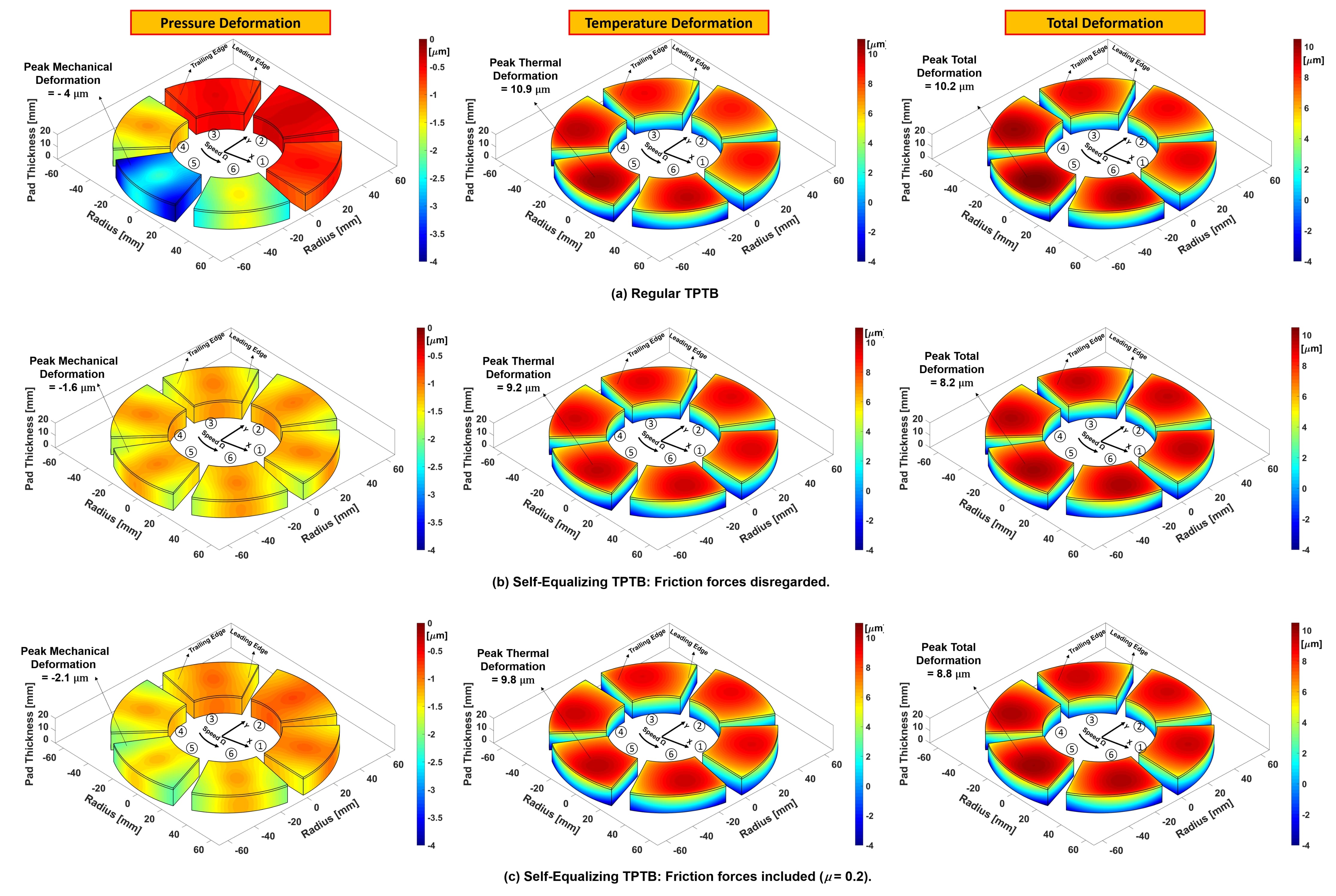

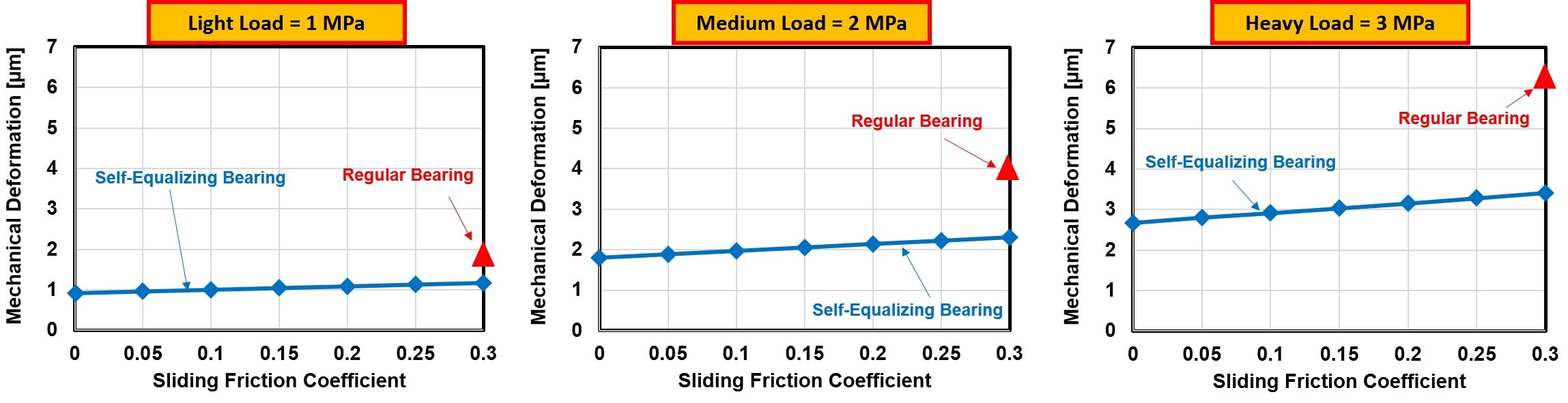

Predicted pad mechanical

deformation for self-equalizing TPTB operating under light to heavy applied

loads vs sliding friction coefficient. Bearing operates with 0.01° thrust

collar (static) misalignment. Applied load per pad = 1 MPa to 3 MPa and rotor

speed = 4krpm.

Publication ŕ Learn more:

1.

Koosha, R., and San

Andres, L., 2019, “Effect of Pad and Liner Material Properties on The Static

Load Performance of A Tilting Pad Thrust Bearing,”

ASME Turbo-Expo 2019, Paper No. GT2019-90231 (Recommended for journal publication).

2.

R. Koosha,

L. San Andrés, 2019 “On the Static Load Performance of a Large Size, Heavily

Loaded Spring Supported Thrust Bearing”, STLE 74th Annual Meeting &

Exhibition, May 19-23, Nashville, Tennessee, USA.

3.

San Andres, L., and Koosha, R., 2018, “A Thermo-Elasto-Hydrodynamic

(TEHD) Computational Analysis of Tilting Pad Thrust Bearings: Analytical and FE

Pad Structure Models,” Annual Progress Report to Turbomachinery Research

Consortium, TRC-B&C-01-018, Texas A&M University, College Station, USA.

URL: http://hdl.handle.net/1969.1/175255.

4.

San Andres, L., and Koosha, R., 2017, “Thermo Hydrodynamic (THD) Computational

Analysis for Tilting Pad Thrust Bearings (TPTBs),” Annual Progress Report to

Turbomachinery Research Consortium, TRC-B&C-05-017, Texas A&M

University, College Station, USA. URL: http://hdl.handle.net/1969.1/175131.

Original by Rasool Koosha

(September 2019)