Identification of force

coefficients in a squeeze film damper with a mechanical seal

MAJOR APPLICATION: Attenuate vibrations and enhance mechanical isolation in Aircraft

Gas Turbines, Power Gas Turbines, Centrifugal

Compressors

Sponsors: Turbomachinery Research

Consortium (03-08) with technical

& grant support from Honeywell AeroSpace (

Objective: To assess effect of end seal on dynamic

forced performance of a test SFD.

Rotating

machinery operation at high speeds induces severe dynamic loading with large amplitude

journal motions at the bearing supports. At these conditions, oil lubricated

dampers with low levels of external pressurization are prone to air ingestion

leading to an inhomogeneous lubricant film with large striations of entrapped

gas. This pervasive phenomenon affects greatly the dynamic force capability and

reduces the reliability of the rotor-bearing system.

Status: properly designed end seals increase the

damping capability of short length SFDs. The test rig accommodates an

industrial contacting mechanical seal SFD. The end seal introduces a dry

friction (non-linear) force into the system. The system dynamic force

coefficients have been identified from circular centered orbit tests. The

parameter identification method allows discerning between the linear (squeeze

film) and non-linear (end seal-dry friction) contributions to the overall

system response. The SFD dynamic response is characterized in terms of squeeze

film damper coefficients, seal dry friction force and added mass coefficients.

Identification of damping and inertia force coefficients for multiple frequency

(non-circular orbits) will be forthcoming in 2008. The tests aim to replicate operating

conditions of intershaft dampers found in multi-spool

turbine engines.

Current Work

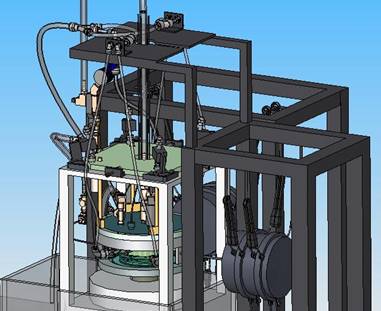

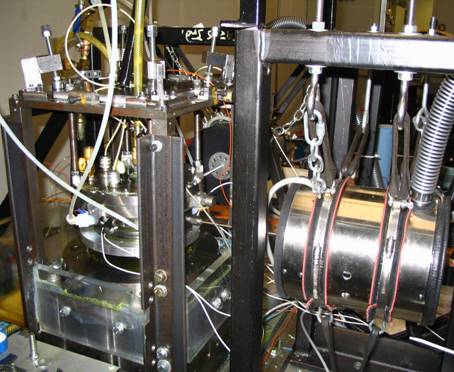

The SFD vertical

test rig was revamped with an end sealed SFD, replicating closely an industrial

application. One damper end is flooded while the other end is fully sealed through

an end seal ring with a wave spring and O-ring. There is a lubricant

recirculation annulus and orifice discharge ports to reduce or eliminate

pervasive air ingestion. Structural parameters of the “dry” system (i.e. with

no lubricant across the SFD land) were identified from static load and impact

load tests .

The objective is to identify the damping and inertia

force coefficients of an end sealed squeeze film damper. The major tasks

are:

2003-07

a)

To measure pressure drop and leakage to

determine the end seal coefficient as a function of pressure, lubricant

temperature (viscosity), wave spring preload, journal centering, and orifice

size.

b)

To perform dynamic load tests (shakers) with lubricated SFD for

increasing oil temperatures and feed pressures.

c)

To develop test and DAQ procedures. Perform analysis of test data

using frequency domain identification techniques to extract SFD force

coefficients (damping and inertia).

Forward estimated parameters as a function of excitation frequency and

amplitude of whirl, lubricant flow rate, feed temperature and pressure, sealing

conditions, etc.

d)

To

validate predictive model with comparisons to experimental values.

2007-08

a)

Conduct

tests with multiple frequency excitations for centered and off-centered bearing

positions to simulate operating conditions in multi-spool gas turbine engines.

b)

Development/adaptation

of identification method for multiple frequency excitation and off-centered

operation.

c)

Increase contact force at the mechanical seal

interface and evaluate its impact on the SFD forced performance for centered

and off-centered operation.

d)

Estimate

parameters as a function of excitation frequency and motion amplitude.

The research

is of interest for applications such as squeeze film dampers in multiple spool gas

turbines, floating ring bearings in turbochargers, hydrodynamic bearings in

compressors, etc.

TEST RIG FACILITY

Squeeze film damping coefficients (CSFDxx,

CSFDyy) versus orbit amplitude

Dynamic pressure measurements

at SFD land and discharge groove, and film thickness.

VIRTUAL

TOUR download video clip (13 MB)

To learn more,

order/read our PUBLICATIONS

Updated May 1, 2008 (LSA)