Rotordynamics & Squeeze

Film Dampers

Funded

by National Science Foundation (1994-97) and TAMU Turbomachinery Research

Consortium (1992-to date)

Squeeze

film dampers (SFDs) provide viscous damping to rotating structures,

allowing for reduction in vibration amplitudes and providing safe isolation

from or of other structural components. SFDs are customarily used in

aircraft jet engines, where rolling element bearings provide little damping to

the rotor-bearing system, and in high performance compressors as retrofit

elements in series with tilting pad bearings to soften bearing supports, reduce

critical speeds, and allow for an extra margin of system stability. Most

aircraft gas turbine engines employ at least one squirrel cage supported

damper.

Squeeze

film dampers derive their behavior from a lubricant being squeezed in the

annular space between a non-rotating journal and a bearing housing. The

journal, typically mounted on the outer race of rolling element bearings,

whirls due to the forces exerted on the rotating shaft. The squeeze film action

generates hydrodynamic pressures and damping forces at the film locations where

the instantaneous gap (film thickness) is decreasing.

Squirrel

cage supported dampers are the most commonly employed SFD design. Most

large aircraft gas turbine engines use at least one, and in many instances, two

or three dampers in one engine. The most distinctive feature of this damper

configuration is the relatively large axial space required in comparison to the

bearing hydrodynamic length.

OBJECTIVES:

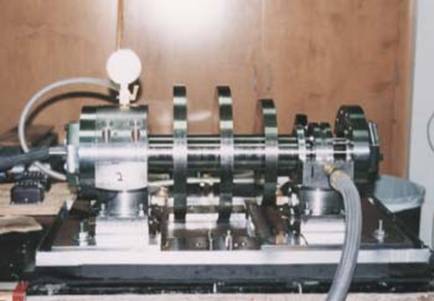

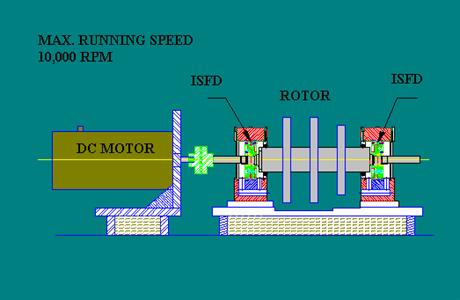

Funds allowed construction of a fully instrumented

test rig for measurement of the imbalance response of a three disk rotor

supported on SFDs (see figures below). The objectives of the research

are:

(a) to provide reliable imbalance

response measurements in a rotor-SFD configuration similar to that of an

aircraft engine,

(b) to develop an empirical model to

predict the forced dynamic performance of SFDs operating with air entrainment leading to a

bubbly air/oil mixture, and

(c) to develop a non-linear SFD-structural

model should the test results from (a) evidence deviations from linear

behavior.

The

first objective, fully completed, comprised the construction of the test

apparatus and measurements of the test rotor in squirrel-cage supported SFDs

and integral SFDs. The rotor-bearing system shows rigid body cylindrical

and conical critical speeds below a top operating speed of 10 krpm. More than

two hundred test measurements have shown the experimental rotor-SFD

response to be linear even for large imbalance levels and off-centered damper

journal operation. The experimental results allow the identification (and

analytical validation) of the damping capability of integral squeeze film

dampers and aid to determine the applicability of this novel technology to

aircraft jet engines. These results have made the third objective irrelevant.

Other

experiments conducted in a controlled orbit SFD rig have shown the

effects of air ingestion on the performance of SFDs. An analytical model

for performance prediction of SFDs with bubbly mixtures has also been

completed.

ROTORDYNAMICS TEST RIG – ROTOR & SFDs

The

Squeeze Film Damper (SFD) rig consistst of a three disk massive rotor

(92 lb) supported on high precision angular contact ball bearings. The outer

races of these bearings are supported on squeeze film dampers. The rotor is

driven by a 10

Additional

instrumentation includes four oscilloscopes, a FFT analyzer, and digital

displays indicating rotor speeds and lubricant temperatures. The facility

includes a 40 gallon oil tank, three gear pumps (one main oil supply pump and 2

return pumps), and 2 forced air convection coolers (for the lubricant and the

drive motor). A Bentley Nevada ADRE for Windows DAIU collects and

processes the test rig vibration measurements. The data processing software

includes real time slow-roll subtraction, order-tracking and synchronous

response filtering. An instrumentation console contains signal conditioners and

digital displays of the operating rotor speed, flow rate, supply pressures and

inlet/exit damper temperatures. The console includes the controls for operation

of the lubrication pumps and the oil cooling and heating elements. Three

oscilloscopes display the rotor orbits at the measurement locations. A fourth

oscilloscope shows the bearing support housing accelerations, and a frequency

analyzer depicts the FFT of selected vibration signals.

STATE OF THE ART TECHNOLOGY: INTEGRAL SQUEEZE FILM DAMPERS (ISFDs)

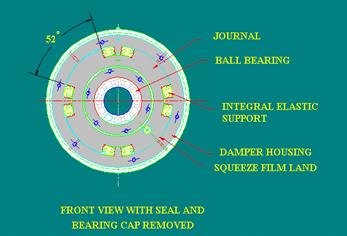

Modern technological advances in metal working allow

the development of integral squeeze film dampers (ISFDs). This ingenious

design is made possible by a wire Electrical Discharge Machining (EDM)

process.

Modern technological advances in metal working allow

the development of integral squeeze film dampers (ISFDs). This ingenious

design is made possible by a wire Electrical Discharge Machining (EDM)

process.

ISFDs are compact

mechanical elements with a length no larger than the bearing itself, and

comprised of arcuate pads attached to a bearing housing via thin wire-EDM

webs. ISFDs can also be machined as split segments allowing rapid

retrofit. Replacement of squirrel cage supported SFDs by integral

dampers brings the following benefits to an aircraft gas turbine engine:

1.

Reduced overall weight and length of the entire aircraft engine structure

2. Elimination of squirrel cage components ISFDs

compact and with reduced number of parts

3. Ability to support axial thrust loads without locking the damper lateral

motion

4. Accurate positioning (centering) by precise design and construction of the

support web stiffness and pad film clearances

5. Split configuration which allows easier assembly and inspection than with

any other damper design

A

comprehensive study of the forced performance of Integral Squeeze Film

Dampers is one of the main objectives of research and further development.

RESEARCH COMPLETED

IN 1996/1997:

RESEARCH COMPLETED

IN 1996/1997:

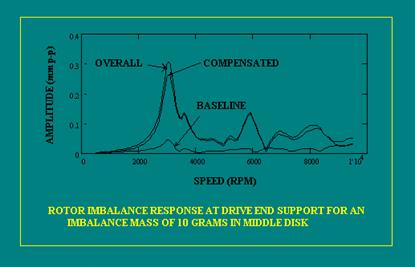

Measurements of the imbalance response of the test rotor supported on open

ends, integral squeeze film dampers (ISFDs) have been completed. The

dampers are compact with integral radial stiffness procured by wire EDM

thin webs. The ISFDs have length and diameter equal to 3.8 inches (96.52

mm) and 0.91 inches (23.0 mm), with a clearance equal to 9 mils (0.229 mm). The

tests are conducted with an ISO VG 10 oil at room temperature (73 F). The

measurements include shaft speed, vibration displacements at six shaft

locations, and two accelerations at the support housings. Other measurements

include oil temperatures, feed pressures and flow rate.

Tests

identifying the structural stiffness of each ISFD verify the design

value (20 klb/in). Measurements of the synchronous rotor response with

increasing imbalance masses are performed from coast-down tests. The measured

vibration peak response at the rotor first critical speed is used to extract

the system damping force coefficients and subsequent identification of the ISFD

damping coefficients. The experiments show the open ended ISFDs to

damp well the rotor response for the cylindrical modes of vibration, with peak

vibration amplitudes proportional to the magnitude of the imbalances. Large

rotor motions up to 80% of the nominal ISFD clearance are measured, and

without shifts in the first critical speed denoting an absence of damper

stiffness hardening. The test system damping coefficients increase slightly

with the amplitude of rotor motion through the first critical speed. From

these, the damping coefficients for the ISFDs are extracted and agree

well with predictions from a full-film open ends, integral damper FEM model.

This model is based on the solution of the classical Reynolds equation without

fluid inertia effects for incompressible, isoviscous fluids flowing through the

thin film land between the flexural pads and the damper housing. Given a

specified damper journal position and instantaneous velocity, the program

calculates the damper reaction forces and damping force coefficients in the

(X,Y) directions.

RESEARCH

COMPLETED IN 1997/98: SEALED INTEGRAL SQUEEZE FILM DAMPERS

Additional work on the experimental

facility includes measurements of the test rotor-ISFD responses to

couple mass imbalances and for ISFDs with end  seals. The goal

is to determine the effect of controlled end gap seals on the integral damper

viscous force coefficients and their influence on the imbalance response of the

test rotor. The measurements also include damper flow-rates and maximum

temperature rise of the lubricant.

seals. The goal

is to determine the effect of controlled end gap seals on the integral damper

viscous force coefficients and their influence on the imbalance response of the

test rotor. The measurements also include damper flow-rates and maximum

temperature rise of the lubricant.

Measurements

of the rotor synchronous response to couple imbalances exciting the conical mode

of vibration further demonstrate the effectiveness of the integral SFDs

to reduce rotor vibrations at this mode. Additional imbalance response

measurements show the effect of controlled end gap seals on increasing the ISFDs

damping coefficients while still allowing for cooling lubricant flow through

the dampers.

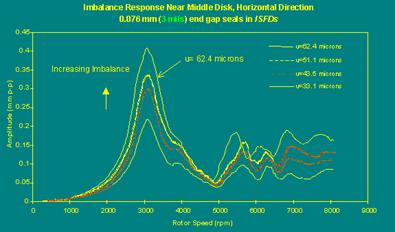

The

synchronous horizontal rotor (p-p) response for increasing levels of rotor

imbalance is shown here for dampers with end seal gaps equal to 3 mils. The

experiments show the sealed ends ISFDs to damp well the rotor response

for the cylindrical mode of vibration and with peak vibration amplitudes

proportional to the magnitude of the disk imbalances. Note that the rotor peak

amplitude for the largest imbalance is nearly 90% of the damper radial clearance

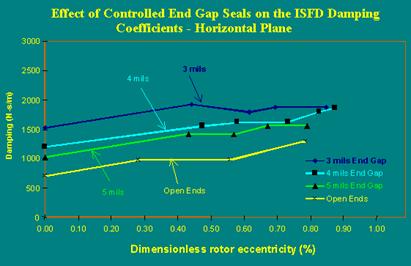

(0.230 mm). Damping coefficients extracted from the peak amplitudes are also

shown below as a function of the peak rotor amplitude for various end gap seal

clearances (3, 4 and 5 mils). Damping coefficients for the open ended dampers

are also included. The damping values at zero rotor eccentricity correspond to

the test results from impact response experiments without rotor spinning.

The paramount

effect of the end seal gap clearance is clearly demonstrated from the

experiments. Tighter end gap seals offer more damping, up to two times the

magnitude obtained with the open ended dampers. However, the most notable

finding is that the damper flow rate is not reduced as the end seal clearance

decreases, thus allowing for the integral dampers to perform their function

satisfactorily without lubricant overheating, as would be the case of a

conventional damper with tight end seals.

The paramount

effect of the end seal gap clearance is clearly demonstrated from the

experiments. Tighter end gap seals offer more damping, up to two times the

magnitude obtained with the open ended dampers. However, the most notable

finding is that the damper flow rate is not reduced as the end seal clearance

decreases, thus allowing for the integral dampers to perform their function

satisfactorily without lubricant overheating, as would be the case of a

conventional damper with tight end seals.

RESEARCH

COMPLETED IN 998-1999: SERIES TILTING PAD BEARING-AND INTEGRAL SF-DAMPER

High

performance, high speed turbomachinery demands appropriate means to ensure

structural isolation of components and stringent rotor vibration limits with

tolerance to sudden imbalance loads due to blade loss events, shock, and

maneuver actions. Squeeze film dampers are an effective mean to reduce

vibrations and to suppress instabilities in high performance aero-engine

systems. Integral squeeze film dampers (ISFDs) offer distinct advantages

such as reduced overall weight and length of the damper structure with less

number of parts, accuracy of positioning (centering), and a split segment

construction allowing easier assembly, inspection and retrofit than with any

other type of damper. Flexure pivot tilting pad bearings offer similar

construction features as the ISFDs while minimizing assembly stack up

tolerances and avoiding pivot wear and fretting. The series combination of a

tilting pad bearing and a squeeze film damper has been implemented in numerous

process compressors in the petrochemical industry to introduce flexibility and

damping to the bearing supports. The proper design of these two mechanical

elements allows for the optimum damping coefficient at the bearing support and

accurate relocation of the (rigid mode) rotor bearing system critical speeds away

from the operating speed range.

High

performance, high speed turbomachinery demands appropriate means to ensure

structural isolation of components and stringent rotor vibration limits with

tolerance to sudden imbalance loads due to blade loss events, shock, and

maneuver actions. Squeeze film dampers are an effective mean to reduce

vibrations and to suppress instabilities in high performance aero-engine

systems. Integral squeeze film dampers (ISFDs) offer distinct advantages

such as reduced overall weight and length of the damper structure with less

number of parts, accuracy of positioning (centering), and a split segment

construction allowing easier assembly, inspection and retrofit than with any

other type of damper. Flexure pivot tilting pad bearings offer similar

construction features as the ISFDs while minimizing assembly stack up

tolerances and avoiding pivot wear and fretting. The series combination of a

tilting pad bearing and a squeeze film damper has been implemented in numerous

process compressors in the petrochemical industry to introduce flexibility and

damping to the bearing supports. The proper design of these two mechanical

elements allows for the optimum damping coefficient at the bearing support and

accurate relocation of the (rigid mode) rotor bearing system critical speeds away

from the operating speed range.

Measurements of

imbalance responses of a test rotor supported on SFDs have been

conducted since 1996. These experiments address to rotor-SFD

configurations typical of aircraft gas turbines where safety and stability

dictate the use of ball bearings instead of fluid film hydrodynamic bearings.

In 1999 we are conducting measurements of the synchronous imbalance response of

the test rotor supported on flexure pivot, tilting pad bearings and integral SFDs.

The major objectives of the experiments are to determine the combined effect of

the hydrodynamic bearings and SFDs on the location of critical speeds

and effective logarithmic decrement, and to demonstrate the effectiveness of

this bearing pair combination on reducing amplitudes of rotor vibration. The

experimental results will allow benchmarking of predictive computational tools

for estimation of force coefficients in both tilting pad bearings and squeeze

film dampers.

Measurements of

imbalance responses of a test rotor supported on SFDs have been

conducted since 1996. These experiments address to rotor-SFD

configurations typical of aircraft gas turbines where safety and stability

dictate the use of ball bearings instead of fluid film hydrodynamic bearings.

In 1999 we are conducting measurements of the synchronous imbalance response of

the test rotor supported on flexure pivot, tilting pad bearings and integral SFDs.

The major objectives of the experiments are to determine the combined effect of

the hydrodynamic bearings and SFDs on the location of critical speeds

and effective logarithmic decrement, and to demonstrate the effectiveness of

this bearing pair combination on reducing amplitudes of rotor vibration. The

experimental results will allow benchmarking of predictive computational tools

for estimation of force coefficients in both tilting pad bearings and squeeze

film dampers.

THE

To learn more, order/read our Publications

ACKNOWLEDGMENTS

The support from National Science Foundation (NSF) and the Turbomachinery

Research Consortium (TRC) is gratefully acknowledged. Thanks to Dr. F.

Zeidan, KMC Bearings, Inc., for his assistance and support.