Effects of air entrainment on response of

squeeze film dampers

Funded by

National Science Foundation (1999-2002) and TAMU Turbomachinery Research

Consortium (1998-2002)

Funded by

National Science Foundation (1999-2002) and TAMU Turbomachinery Research

Consortium (1998-2002)

High

performance turbomachinery demands the largest power to weight ratios at ever increasing

speeds and light-flexible rotors. These requirements accentuate the two most

commonly recurring problems in rotordynamics, namely excessive steady-state

synchronous vibration and sub harmonic rotor instabilities. Squeeze film

dampers (SFDs) are virtually the only means to introduce damping in aircraft

jet engines and commercial compressors. SFDs have been successfully used to

solve these problems, stabilizing otherwise unstable units. As with most

hydrodynamic bearings, the classical Reynolds equation for thin film

lubrication is generally used to model squeeze film dampers. However,

researchers and users have recurrently reported important discrepancies between

theory and practice.

Our

work in the Laboratory focused on understanding the complex phenomena occurring

in SFDs.

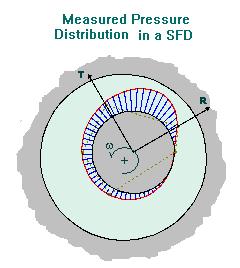

A SFD

comprises of a cylindrical housing, a journal and a thin lubricant film. In

SFDs the journal is typically mounted on ball bearings and does not spin, only

whirls with the shaft. As a result, the hydrodynamic (damping) forces generated

are reactions to the whirling journal velocity. The figure shows a typical

experimental pressure distribution in a SFD as measured in a laboratory test apparatus.

The

pressure profile shown lacks symmetry due to the presence of air in the

lubricant, and which is generally acknowledged to be one of the main sources of

discrepancy between theory and practice. It is generally accepted that, under

high speed operation with high vibration levels, a damper drags air into the

film or releases air that is in solution within the oil. This phenomenon

produces a bubbly mixture of oil and air that replaces the (pure) lubricant,

and is generally misnamed as gaseous cavitation. The resulting complex squeeze

Current

models for the design of SFDs are extensions of the theory developed for

journal bearings. The classical Reynolds equation is solved and boundary

conditions for the definition of a vapor cavitation zone are applied to the

computed pressures. The left figure above shows a measured pressure field that

would agree with such models. In this case, the only effect of the cavitation

by lubricant vaporization is the occurrence of a cavitation zone in which the

pressure is constant and equal to the lubricant vapor pressure at the operating

temperature. The vapor cavitation zone is clearly delimited and repeatable,

thus rendering a predictable cyclic pressure field. Unfortunately, to obtain

this kind of behavior some unusual requirements should be fulfilled. For the

measurements presented, the SFD had to be operated fully submerged in oil and

with a relatively high supply pressure.

Unfortunately,

most SFDs operate with low levels of external pressurization and are open to

the ambient on the sides, thus allowing the formation of a bubbly mixture in

the film as mentioned before. Operation under these conditions results in

completely different pressure profiles, as shown in the figure to the right.

The most noticeable difference is that now the pressure field does not repeat

itself for every cycle of journal motion. Random

The

figures below show the stationary cavity developed by vapor cavitation in a

steadily loaded journal bearing and the bubbly mixture formed in an orbiting

SFD. Click on the pictures to see more information about them.

Vapor

cavitation on a journal

bearing Bubbly

Lubricant in a SFD

The TRC-SFD test rig is set up for the study of

gaseous cavitation in SFDs. The damper journal is mechanically constrained to perform

circular centered orbits. The dimensions of the open-end damper tested are, Diameter=129

mm, Length=31 mm, Clearance=0.343 mm. The apparatus is

instrumented with four piezoelectric pressure transducers, two strain gage

pressure transducers, two eddy-current displacement sensors, one optical

tachometer, one thermal air mass

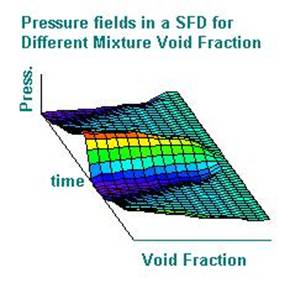

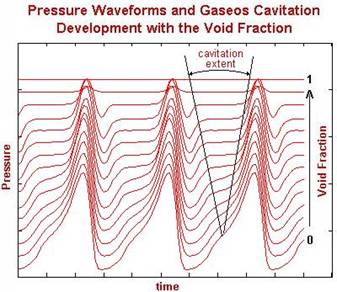

The

experimental results correlate the appearance and extent of a zone of constant

pressure, or null pressure generation, with the introduction of air in the

lubricant (void or volume fraction)as shown in the figuresbelow. A 3D representation

of these test results shows a different perspective, and makes evident how the

occurrence of the gaseous cavitation zone results in a reduction of the

squeeze film pressure generation.

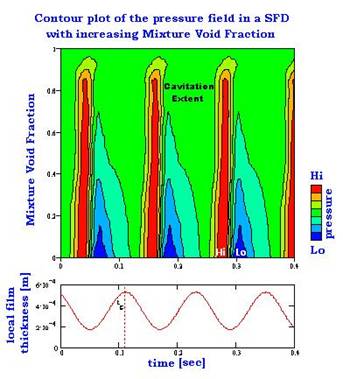

The

measured pressure depicted on the graphs is absolute and makes evident how the

zone of constant pressure takes the value of the pressure at the damper

exit (discharge plane). The contour plot at the right correlates the

squeeze pressure with the local film thickness as a function of time for

different mixture (void fraction) conditions, and shows that the

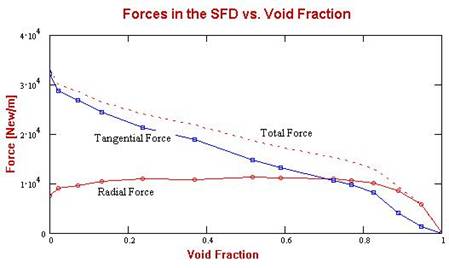

The

major objectives of the research were to determine experimentally the effect

that air entrainment has on the performance of the SFDs and to develop a model

quantifying these effects so as to enhance our understanding of squeeze film

dampers. The tests and model aid in the design of new dampers and modification

of old ones. Ultimately, the damper hydrodynamic forces exerted on the journal

become the most important factors to be studied, since these forces directly

affect the dynamics of a rotor-bearing system employing SFDs. The experiments

have shown that the presence of air in the lubricant results in reduction of

the damping forces as shown below.

Experimental radial and tangential forces vs air volume content

The

research completed the analysis of the pressures and forces to develop a

semi-empirical theoretical model that accounts for the dynamics of the bubbles

within the lubricant. Modifications to the test rig to perform

è To learn more, order/read our Publications

ACKNOWLEDGMENTS

The support from National Science Foundation (NSF) and the

Turbomachinery Research Consortium (TRC are gratefully acknowledged.